What is Outdoor Battery Cabinet

An outdoor battery cabinet stores electricity in lithium cells inside a weatherproof steel enclosure. The enclosure holds the cells, the electronics that monitor them, the power converter that interfaces with the grid, cooling equipment, and fire suppression. Protection rating runs IP54 or higher. Operating temperature spans minus 20°C to plus 55°C.

That covers the basic definition. The definition explains nothing about why this product category exists or what makes one cabinet worth buying and another worth avoiding.

The Real Problem

Lithium cells demand conditions that outdoor environments refuse to provide.

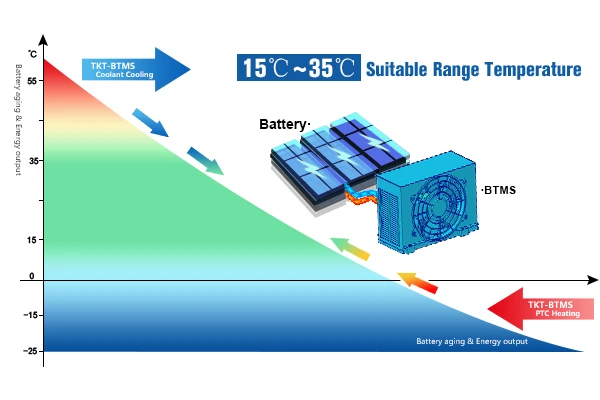

Cells want 25°C. They tolerate 15°C to 35°C without major penalty. Push beyond that range and degradation accelerates. At 45°C, aging roughly doubles compared to 25°C. Below zero, charging causes lithium metal to plate onto the anode, permanently reducing capacity and creating internal short circuit risk.

Cells want uniform temperature. A 5°C spread between the hottest and coolest cell in a pack causes the hot cell to age faster than the cool cell. After a thousand cycles, the weakest cell limits the entire system. The capacity that remains in the healthy cells becomes inaccessible.

Outdoor environments offer none of this. A cabinet in Xinjiang sees 45°C summers and minus 30°C winters. A cabinet in Hainan deals with 95% humidity and salt air. A cabinet in Tibet operates at 4500 meters where air density drops 40% and cooling systems lose effectiveness proportionally.

The outdoor battery cabinet exists to create artificial climate control for cells that cannot survive natural climate. The companies that do this well thrive. The companies that treat it as a commodity enclosure with commodity components discover that their systems degrade faster than the financial models predicted. In 2024, over 17,000 energy storage companies in China dissolved. Most of them understood battery chemistry. Few of them understood the thermal engineering required to keep cells alive in hostile environments for fifteen years.

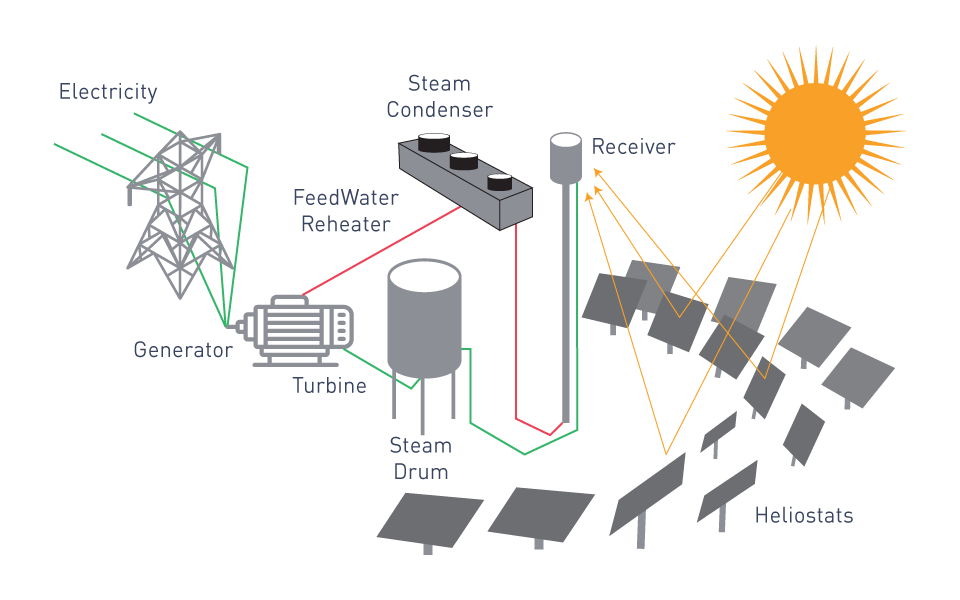

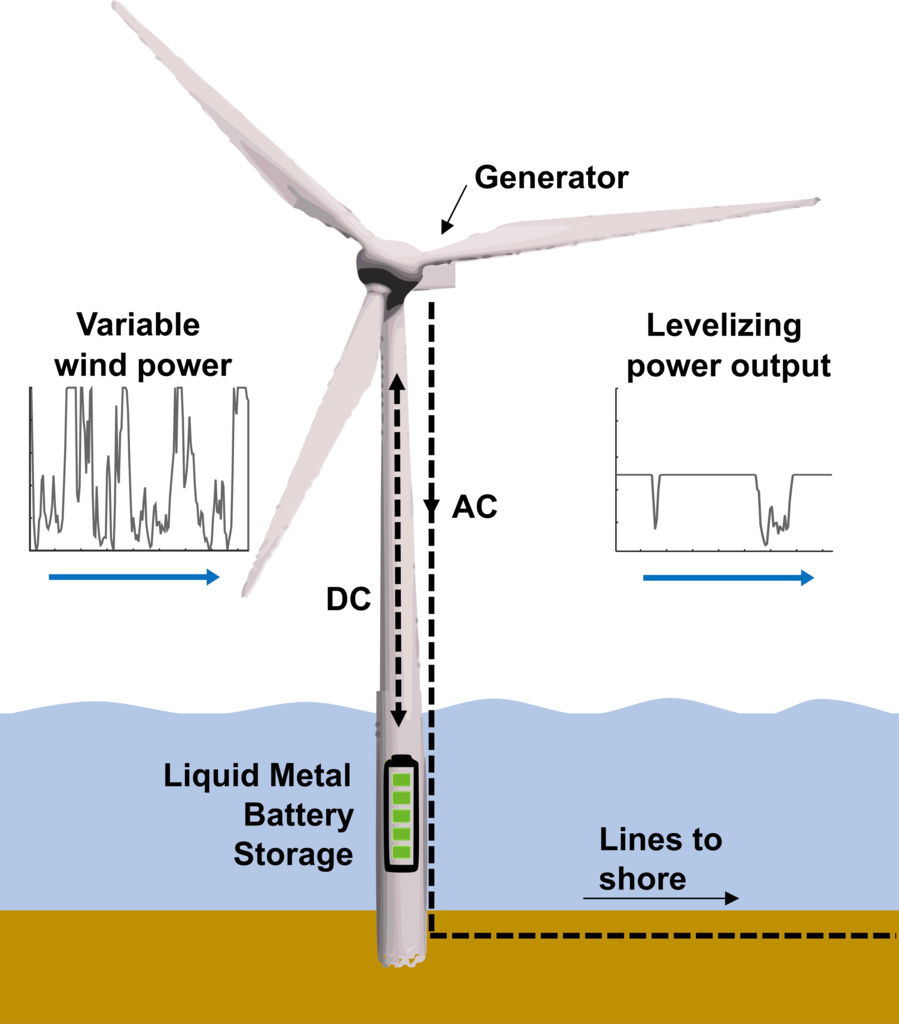

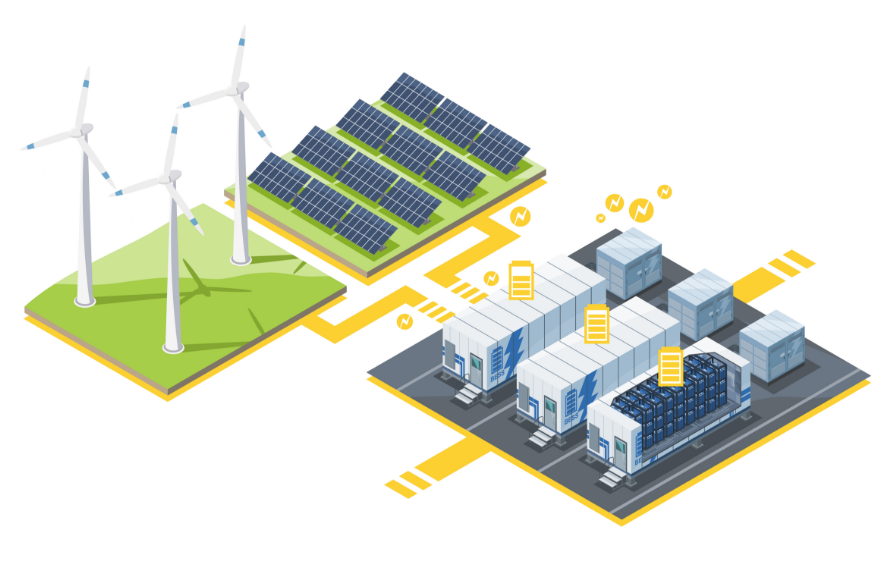

Energy storage systems integrated with renewable power generation

Cells

Lithium iron phosphate chemistry holds 98% market share in stationary storage. This concentration reflects physics rather than fashion.

The competing option, ternary lithium using nickel-cobalt-manganese cathodes, stores 30-40% more energy in the same volume. For electric vehicles where every kilogram matters, that density advantage justifies the higher cost and risk. For a cabinet sitting on a concrete pad, weight and volume carry no penalty. The density advantage buys nothing.

What ternary chemistry brings instead is thermal instability. The cathode material begins decomposing at roughly 200°C. Decomposition releases oxygen. The oxygen feeds combustion. The combustion raises temperature. Temperature accelerates decomposition. Once the cascade starts, it continues until fuel exhausts. Water cannot stop it because the fire generates its own oxidizer internally.

Lithium iron phosphate decomposes at 700°C. It does not release oxygen. A nail driven through a cell produces smoke and flame but not explosion, not self-sustaining combustion, not propagation to neighbors.

A storage cabinet contains three thousand cells packed centimeters apart. The thermal stability margin between 200°C decomposition and 700°C decomposition determines whether a single cell failure stays a maintenance ticket or becomes a news story.

South Korea learned this between 2017 and 2019 when 23 storage facilities caught fire. Nearly all involved ternary chemistry. The entire Korean storage industry suspended operations for two years. Projects were demolished, insurers withdrew coverage, regulations were rewritten. The country that pioneered large-scale battery storage ceded its lead to Chinese manufacturers who had already committed to lithium iron phosphate.

Cell Capacity and the Thermal Trap

Cell capacity has increased from 280Ah in 2022 to 587Ah and 684Ah in 2025. The arithmetic looks attractive: a 100kWh system needs 110 cells at 280Ah versus 52 cells at 600Ah. Fewer cells means fewer connections, fewer welds, fewer potential failure points.

The thermal arithmetic tells a different story.

Heat generates inside the cell during charge and discharge. The heat must conduct from the interior to the surface before cooling systems can remove it. Larger cells have longer conduction paths. The center-to-surface distance in a 600Ah cell exceeds the distance in a 280Ah cell by roughly 40%.

Lithium battery materials conduct heat poorly. Thermal conductivity runs 1-3 W/m·K, two orders of magnitude below aluminum. When discharge rate increases, heat generation rises faster than conduction can remove it. The center temperature climbs while the surface temperature stays manageable. Temperature sensors mounted on surfaces report acceptable readings while the interior cooks.

At 280Ah, air cooling kept center-edge temperature differentials under 5°C in most operating conditions. At 500Ah and beyond, air cooling produces 8°C differentials routinely and 12°C differentials during aggressive discharge.

What happens to a cell with 12°C internal temperature spread? The hot region ages faster than the cool region. After three years, the hot region might retain 85% capacity while the cool region retains 95%.

The battery management system detects the weakest zone and limits the entire cell accordingly. The accessible capacity drops even though most of the cell remains healthy.

This constraint couples large cells to liquid cooling with no exceptions. Any vendor claiming air-cooled performance with 500Ah cells either operates them gently, accepts the lifecycle penalty, or avoids discussing the thermal reality. The industry has collectively decided that the manufacturing simplicity of larger cells justifies the thermal management complexity they demand. Whether individual buyers understand that tradeoff determines whether their fifteen-year projects actually deliver fifteen years.

Consistency

Manufacturing tolerances produce cells with 2-3% capacity variation within a production batch. This variation amplifies through operation.

The mechanism is straightforward. Cells with slightly higher capacity experience shallower charge-discharge cycles relative to their capacity. Shallow cycling is gentle. Gentle cycling degrades slowly. Cells with slightly lower capacity experience deeper cycling relative to their capacity. Deep cycling is harsh. Harsh cycling degrades quickly.

The initial 3% spread becomes 6% after five hundred cycles. It becomes 10% after a thousand cycles. System usable capacity tracks the weakest cell because protection logic prevents overdischarging any individual cell. The spread that started as manufacturing noise becomes the binding constraint on system performance.

Cell sorting addresses this problem at the source. Premium manufacturers sort cells to millivolt precision before shipping. Batch consistency stays within 1%. The sorting requires test equipment investment that commodity manufacturers cannot justify. The price difference between premium and commodity cells reflects sorting precision more than any other factor.

Procurement departments that evaluate cells on price per kilowatt-hour miss this dynamic. Procurement departments that request batch consistency histograms from suppliers catch the manufacturers who skip sorting to hit lower price points.

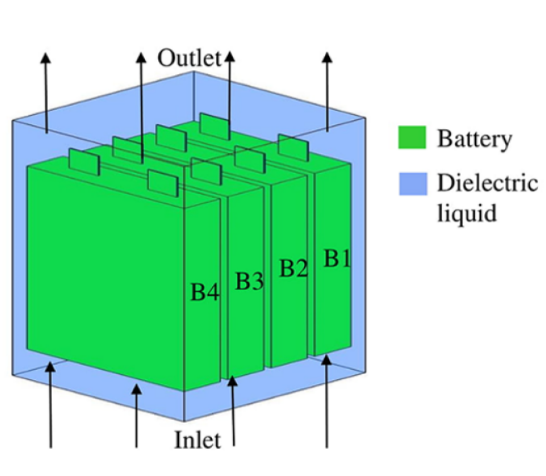

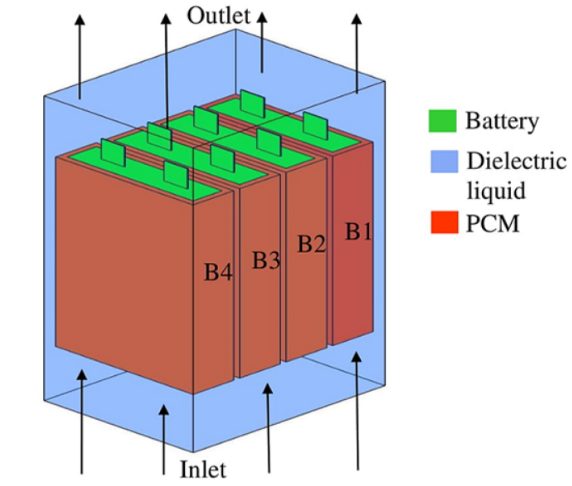

thermal management systems

Thermal Management

Thermal management determines whether a storage system lasts eight years or fifteen years. Nothing else in the cabinet comes close to this impact on lifecycle economics.

Why Air Cooling Is Dying

Air cooling works by blowing conditioned air across cell surfaces. The heat transfer coefficient, measuring how effectively heat moves from surface to air, runs 25-100 W/m²·K depending on airflow velocity and channel geometry. This coefficient limits how much heat the system can remove per degree of temperature difference between cell and air.

At 280Ah cell sizes with moderate discharge rates, air cooling handled the thermal load. The cells generated heat slowly enough that airflow could remove it without excessive temperature rise.

At 500Ah cell sizes with the same discharge rates relative to capacity, heat generation per unit surface area increases. The same airflow cannot keep pace. Temperature rises. Either discharge rate must decrease (reducing system capability) or temperature differential must increase (reducing system life).

Air cooling carries a second limitation that became important as deployments spread to harsh environments. Air cooling requires intake and exhaust openings. The cabinet cannot be sealed. Protection ratings top out at IP54, meaning protection against dust ingress but not complete sealing, protection against splashing water but not jets or immersion.

IP54 suffices for installations in temperate climates with clean air. It does not suffice for coastal installations where salt spray corrodes anything it contacts. It does not suffice for desert installations where sand infiltrates any opening. It does not suffice for tropical installations where humidity combines with temperature swings to produce condensation inside electronics.

The storage industry spent years installing air-cooled cabinets in environments they could not survive. Warranty claims accumulated. Insurers increased premiums. Operators learned that the cabinet that cost 20% less to purchase cost 50% more over ten years when replacement parts and degraded performance factored in.

Liquid Cooling

Liquid cooling circulates glycol-water mixture through channels machined into aluminum plates pressed against cell surfaces. The heat transfer coefficient runs 500-1000 W/m²·K, ten times the air cooling range. The same temperature differential removes ten times the heat.

Liquid cooling is a closed loop. The cabinet can be completely sealed. Protection ratings reach IP65 or IP67 without compromise. Salt spray, sand, humidity pose no threat to sealed enclosures.

Temperature uniformity improves dramatically. Air temperature rises as it flows past successive cells, producing front-to-back gradients of 5°C or more. Liquid flow rate can be adjusted to minimize inlet-outlet temperature rise. Cell-to-cell temperature spread drops below 3°C.

The cost premium runs 30-50% above air cooling. The complexity increases with additional components: chiller, pump, expansion tank, cold plates, plumbing, leak detection. Each component can fail. Maintenance requirements increase.

The lifecycle economics favor liquid cooling decisively when cell prices are considered.

A project designed for fifteen years with air cooling and 500Ah cells might achieve twelve years before the weakest cells degrade below usable threshold. Cell replacement at year twelve costs 60-65% of original system price. The total cost of ownership includes the original purchase plus replacement cells plus installation labor plus lost revenue during replacement.

The same project with liquid cooling might achieve fifteen years without cell replacement. The additional upfront cost for liquid cooling is recovered many times over through avoided replacement.

This calculation drives the market transition. Air cooling held 65% share in 2024. Liquid cooling share rises toward 50% in 2025 and will exceed 70% by 2027. Air cooling retreats to small systems and budget installations where thermal loads stay manageable and lifecycle expectations stay modest.

Liquid Cooling Design Details That Matter

Liquid cooling systems vary enormously in implementation quality. The label "liquid cooled" does not guarantee adequate thermal performance.

Cold plate design determines how uniformly heat transfers from cells to coolant. Cells do not have perfectly flat surfaces. Manufacturing tolerances leave slight waviness. A rigid cold plate pressed against a wavy cell surface contacts only the high points. Air gaps at the low points insulate rather than conduct.

Quality designs interpose thermal interface material between cold plate and cell. The material is soft enough to conform to surface irregularities, filling gaps. It must be thin enough to avoid adding significant thermal resistance. It must be stable over the twenty-year service life without drying out, cracking, or losing compliance.

Flow channel geometry determines coolant velocity distribution. Coolant entering a cold plate tends to take the path of least resistance. If channel resistance varies, flow concentrates in low-resistance paths while high-resistance paths see reduced flow. The cells adjacent to low-flow channels run hotter than cells adjacent to high-flow channels.

Quality designs use computational fluid dynamics to optimize channel geometry for uniform flow distribution. Budget designs use simple serpentine patterns that produce significant flow imbalance.

Coolant composition requires climate-specific optimization. Pure water offers superior heat transfer but freezes at 0°C. Ethylene glycol depresses freezing point but degrades heat transfer capacity. A 50% glycol mixture resists freezing to minus 40°C but transfers roughly 20% less heat than pure water. Installations in mild climates can use lower glycol concentrations for better thermal performance. Installations in cold climates need higher concentrations to prevent freeze damage.

Pump sizing determines both thermal performance and parasitic power consumption. Larger pumps move more coolant, reducing temperature rise through the loop. Larger pumps also consume more power, subtracting from net system efficiency. A liquid cooling system might consume 2-4% of system throughput in auxiliary power. Poor pump sizing can push this toward 6%.

These details separate liquid cooling systems that deliver promised performance from systems that merely check the "liquid cooled" box on a specification sheet.

Battery Management System

The battery management system monitors cells, estimates charge state, balances cell-to-cell variation, and enforces protection limits during abnormal conditions.

State of charge estimation is the challenging function. The textbook approach integrates current over time. Current sensor error accumulates through integration. Capacity shifts with temperature and age. After fifty cycles, pure integration drifts 10% or more from reality.

Functional estimation combines integration with voltage-based calibration, Kalman filtering for error correction, and aging models. Quality systems achieve 1-2% accuracy. Budget systems drift to 5-10%.

The accuracy matters because protection logic uses estimated state of charge to prevent overdischarge and overcharge. A system that believes it has 20% charge remaining when it actually has 25% stops discharging prematurely. A system that believes it has 100% charge when it actually has 95% stops charging prematurely. Both errors reduce usable capacity below nameplate specification.

Balancing corrects for cell-to-cell drift. Passive balancing dissipates excess energy through resistors. Active balancing transfers excess energy between cells through inductors. Active balancing preserves the energy that passive balancing wastes. The efficiency difference, 2-3% over system lifetime, accumulates to meaningful revenue difference for commercial projects.

Power Conversion System

The power conversion system converts DC from batteries to AC for grid connection and reverses the process during charging. Nameplate efficiency reaches 98% at full load.

Actual operating efficiency runs lower because storage systems rarely operate at full load. At 20% load, fixed switching losses and gate drive losses consume a larger fraction of throughput. Efficiency might drop to 92%.

Transfer time between grid-connected and island mode determines whether critical loads experience interruption during grid faults. Twenty milliseconds is the threshold where most equipment rides through without reset. One hundred milliseconds causes servers to restart and processes to abort.

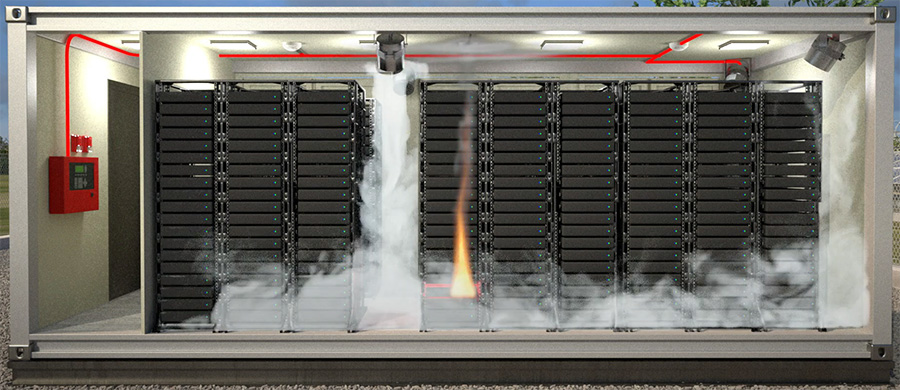

Fire suppression systems engineered for lithium battery protection

Fire Suppression

Lithium battery fires involve gas deflagration rather than ordinary combustion. Thermal runaway releases hydrogen and carbon monoxide. Internal chemical reactions sustain heat independent of external oxygen. Water slows but does not stop the process.

Detection must precede full runaway. Off-gas detection identifies electrolyte vapors ten minutes before thermal runaway reaches propagation temperature. This window allows protective action.

Suppression uses fluorinated ketones to extinguish flame without residue or electrical conductivity. Fluorinated ketones cool poorly. Effective systems combine them with water mist for sustained cooling.

Market Position

Global storage installations reached 175GWh in 2024. Chinese manufacturers supplied over 93% of cells. The supply chain concentration reflects manufacturing scale and cost structure that competitors have not matched.

Trade policy is restructuring the market. US tariffs and subsidies redirect investment toward North American production. European carbon disclosure requirements create compliance barriers. Middle Eastern buyers fund local manufacturing partnerships.

The outdoor battery cabinet product form will persist regardless of which companies manufacture them or where production locates. Modular format, standardized interfaces, rapid deployment capability match distributed storage requirements too precisely to be displaced.

Selection

Cell consistency data matters more than cell capacity specification. Request batch histograms from suppliers.

Thermal management design matters more than thermal management label. Probe cold plate construction, interface material, flow distribution, pump sizing.

Partial load efficiency matters more than peak efficiency. Request efficiency curves across the operating range.

Lifecycle cost matters more than purchase price. Model degradation, efficiency loss, potential replacement against savings from cheaper initial purchase.

Brand survival matters for warranty coverage. The industry consolidation that eliminated 17,000 companies in 2024 continues. Whether a supplier exists in year eight when warranty claims arise depends on current financial health and market position.