Four types of batteries power electric golf carts: flooded lead-acid, AGM, gel, and lithium. Flooded lead-acid has been around forever and remains the default because it costs the least upfront. AGM sealed up the case and eliminated watering. Gel was supposed to be better for deep discharge but never caught on. Lithium changed the game when prices finally dropped enough for normal people to afford.

Most golf cart owners end up with flooded lead-acid because that's what the dealer stocks and what the previous owner installed. The choice usually happens by default rather than analysis. But the differences matter. Pick wrong and the batteries either die early from neglect or drain the wallet through unnecessary premium.

Flooded Lead-Acid

The flooded lead-acid battery is a 19th century invention that refuses to die. Lead plates sit in sulfuric acid. Electricity flows. Chemistry happens. The reaction reverses when you charge. Simple, cheap, and proven across billions of units over more than a century.

The "flooded" part means liquid acid sloshes around inside. This creates the defining maintenance headache: water evaporates during charging and needs replacement. Skip the watering and the plates dry out and die. The interval varies by climate and usage but figure on checking every couple weeks during heavy use. Arizona in July demands more attention than Minnesota in spring. Use distilled water only. Tap water minerals contaminate the chemistry and shorten life. People learn this the hard way all the time.

A gallon of distilled water costs a couple dollars at the grocery store. The watering process takes maybe fifteen minutes once you've done it a few times. Pop off the caps, look inside with a flashlight, add water to any cells that look low, wipe up spills, put caps back on. Not complicated. Not time consuming. Yet somehow it doesn't happen.

Everyone says they'll keep up with watering. Few actually do. The batteries punish this dishonesty. A set that could last five or six years with proper care often dies in three because the owner forgot about it for a month during summer. The plates oxidize where exposed to air. That capacity never comes back. No amount of charging or equalization fixes it. Dead is dead.

A friend bought a house with a golf cart in the garage. Sat there for a couple years. The batteries looked fine from outside. He charged them up, drove maybe two holes worth of distance, and the cart died. The cells had gone dry. Every plate was sulfated and oxidized. Eight batteries, maybe two years old originally, completely destroyed by neglect. He could have bought new batteries or tried some desulfation gadget, but he was already irritated about the whole thing and sold the cart instead.

Commercial golf courses get good life from flooded batteries because maintenance crews follow schedules. They check water levels weekly, clean terminals monthly, and keep logs. Private owners rarely maintain this discipline. The gap between rated cycle life and real-world results is huge for flooded batteries specifically because the chemistry is unforgiving of neglect.

Sulfation is the other killer. Lead sulfate forms on the plates during discharge. Charging reverses most of it but never all. The residue accumulates over hundreds of cycles until the battery can't hold a charge. Leaving batteries partially discharged accelerates sulfation badly. A few weeks sitting at half charge does more damage than months of daily use. Hot storage temperatures speed up crystal growth.

Winter storage causes a lot of sulfation deaths. The cart sits in the garage from November to April. Owner figures the batteries will be fine. Maybe they meant to put them on a maintenance charger but didn't get around to it. By spring the batteries have self-discharged to forty or fifty percent and sat there for months building up sulfate crystals. First drive of the season goes okay. Second drive the cart feels sluggish. By June it barely makes it around the neighborhood. The batteries aged years during those idle months.

A maintenance charger or float charger prevents winter damage. These devices plug into the wall and clip onto the battery terminals. They supply just enough current to offset self-discharge without overcharging. Cost is minimal. The discipline required is plugging them in and leaving them plugged in until spring. People who do this get long battery life. People who mean to do this but don't are back buying batteries in a couple years.

Temperature matters for storage. Batteries stored cold sulfate slower than batteries stored warm. A cart in an unheated garage in Minnesota survives winter better than a cart in a heated garage in Arizona. But cold batteries shouldn't be charged until they warm up, which means even with a maintenance charger, cold storage batteries should be brought above freezing before charging resumes. The optimal winter storage involves moderate temperatures, a float charger, and monthly checks. Few private owners hit this target.

Trojan dominates the commercial fleet market. Their T-105 has been the standard for decades. Crown and US Battery make comparable products at similar prices. Interstate and Duracell sell rebranded batteries at slightly lower prices. Cheap no-name batteries from Amazon marketplace sellers are a gamble. Some work fine. Others fail early with no warranty recourse because the seller disappeared. The battery sitting in an Amazon warehouse might have sat there for a year already, slowly sulfating before it even gets installed.

The voltage configuration question confuses buyers. A 48-volt cart can use eight 6-volt batteries, six 8-volt batteries, or four 12-volt batteries. All three add up to 48 volts but the internal construction differs.

The 6-volt option lasts longest because those batteries have thicker plates. Fewer cells per battery means more lead per cell. More lead means more material to wear away before the battery dies. The 12-volt configuration is convenient but the thinner plates wear faster. The plates have to be thin because fitting six cells into the same size case as three cells leaves less room per cell. Most fleet operators stick with 6-volt for this reason. The extra connections and extra maintenance points are worth the longer service life when running hundreds of carts.

For private owners, the configuration question is less clear. Eight batteries means eight things to check and maintain. Four batteries means four things. Some people prefer the simplicity even knowing they're trading some longevity. Others don't care about the extra work and want maximum life. Either approach works as long as the choice is conscious.

Charging flooded batteries produces hydrogen gas. The electrolysis that boils off water also splits some water molecules into hydrogen and oxygen. Hydrogen is explosive above certain concentrations. Golf cart battery compartments have vents for this reason. Blocking the vents with storage items or aftermarket covers is genuinely dangerous. Sealed battery types eliminate this concern entirely. Nobody has to think about garage explosions with AGM or lithium.

Terminal corrosion is the other maintenance item. Acid vapor escapes through the vents and settles on the terminals. Over time a crusty white or greenish buildup forms. This buildup increases electrical resistance. High resistance means the charger works harder to push current in and the motor gets less current out. Performance degrades gradually. Cleaning terminals with baking soda solution and a wire brush takes ten minutes and should happen a few times a year. Applying dielectric grease after cleaning slows down future corrosion.

Flooded lead-acid batteries are the cheapest to buy and the most demanding to own. They work well for people who actually maintain things. They work poorly for people who mean to maintain things but don't follow through. Most private owners fall into the second category and would save money over time with a different battery type despite higher initial cost.

AGM

AGM stands for Absorbent Glass Mat. The technology wraps fiberglass around the lead plates and soaks up all the acid. No free liquid remains inside. The case is sealed. No watering needed. No acid spills possible. No hydrogen venting to worry about.

The aerospace industry developed AGM for applications where maintenance access was impossible. Satellites can't be refilled. Military equipment operates in conditions where acid spills are unacceptable. The technology filtered down to consumer applications where people wanted sealed batteries that could be mounted in any orientation and forgotten about.

Golf carts adopted AGM for the convenience of never adding water. The sealed case also means no terminal corrosion from acid vapor. Maintenance drops to almost nothing. Charge them, use them, charge them again. That's it.

Performance improves modestly over flooded. The compressed construction reduces internal resistance, which means slightly stronger acceleration and hill climbing. Vibration resistance is better because nothing sloshes around inside. Self-discharge rate drops, so batteries sitting unused hold charge longer. These differences are real but not dramatic. Nobody switches from flooded to AGM because their cart suddenly became a hot rod. The switch happens because they got tired of watering.

The problem is overcharge sensitivity. Sealed batteries can't vent gas safely the way flooded batteries can. Overcharging builds pressure until gas escapes through relief valves. That gas is gone forever. Flooded batteries lose water to overcharge but the water can be replaced. AGM capacity loss from overcharge is permanent.

This makes charger compatibility critical. Most golf cart chargers before 2015 or so were designed for flooded batteries. Those chargers push voltage too high for AGM. Running AGM on a flooded charger causes slow but certain death over twelve to eighteen months. The damage is invisible until capacity suddenly collapses. The owner thinks they got bad batteries when really they killed good batteries with the wrong charger.

Proper AGM chargers use different voltage profiles and terminate charging based on current draw rather than time. A decent smart charger with AGM settings costs a few hundred dollars. Buyers converting from flooded to AGM need to factor in charger cost or verify their existing charger supports AGM profiles. Many modern chargers have multiple settings selectable by switch or automatically detected. Older chargers are usually flooded-only.

The charger verification step gets skipped constantly. Someone buys AGM batteries, installs them, plugs in the same charger that came with the cart, and figures everything is fine because the charger turns on and the batteries accept current. The charger might even show "full" after a few hours. What's actually happening is overcharge at slightly elevated voltage each cycle. The batteries don't fail immediately. They lose a few percent capacity per month until suddenly the cart can't finish a round. By then the damage is done and new batteries are needed. The owner blames the battery brand when the charger was the problem.

Some golf cart forums recommend just using the old charger anyway because "it works fine." The people giving this advice either got lucky with a charger that happens to have compatible voltage limits, or they haven't owned their AGM batteries long enough to see the damage accumulate. The chemistry doesn't lie. Overcharging sealed batteries destroys them. Sometimes quickly, sometimes slowly, but always.

Fullriver and Lifeline make quality AGM batteries. Odyssey is excellent but prices near lithium territory, which raises the question of why not go lithium instead. Cheap AGM batteries from unknown brands often use thinner plates and fail early. The failure looks the same as flooded failure: gradual capacity loss until the cart won't make it around the block.

AGM solves the watering problem at roughly double the cost of flooded. For owners who wouldn't maintain flooded batteries properly, AGM actually costs less in the long run because the batteries last their full rated life instead of dying early from neglect. For disciplined owners who would water flooded batteries correctly, AGM pays for convenience but not necessarily longer service.

Gel

Gel batteries mix silica into the acid to create a thick paste. The gel can't spill and enables sealed construction like AGM. The technology handles deep discharge better than other lead-acid types.

Almost nobody uses gel batteries in golf carts anymore.

The charging requirements killed market adoption. Gel batteries need lower voltage than AGM during charging. Exceeding the limit creates permanent damage. The gel develops internal voids that never heal. AGM chargers are too aggressive for gel. Flooded chargers destroy gel batteries quickly. Only gel-specific chargers work, and those cost extra and are harder to find.

The deep discharge advantage sounds good on paper. Gel tolerates being run down further than flooded or AGM without damage. But typical golf cart use doesn't discharge that deeply. A round of golf uses maybe a third to half of battery capacity. Neighborhood driving is similar. The extra deep discharge tolerance provides no practical benefit for normal use patterns.

Gel batteries made sense for solar installations and marine applications where deep cycling was unavoidable and custom charging infrastructure could be specified from the start. Solar panels push whatever current the sun provides. Boats sit on marine chargers designed for the specific battery type. Golf carts get plugged into whatever charger came with them. The charger mismatch problem is too common and too damaging.

Deka and MK Battery make reliable gel batteries. Prices run higher than AGM. Unless operating conditions specifically require deep discharge tolerance think commercial resort shuttles running all day gel offers no advantage over AGM and several disadvantages. Skip it.

Lithium Iron Phosphate

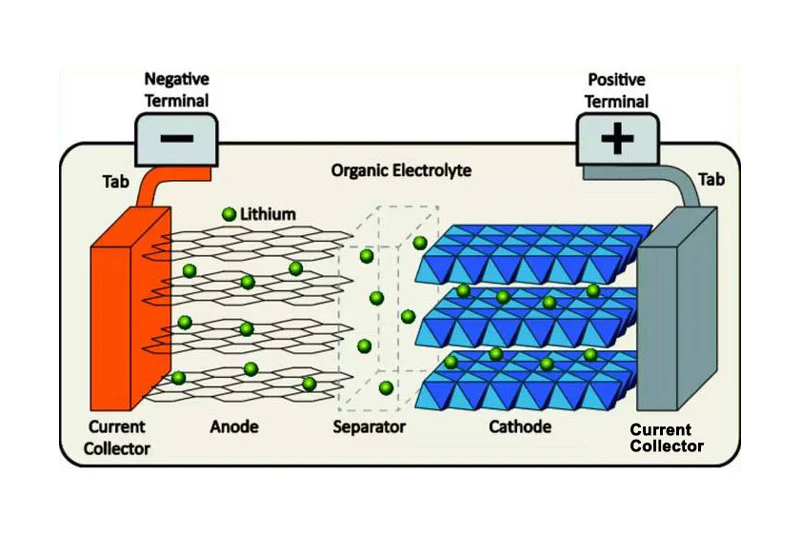

Lithium batteries store energy through a completely different mechanism than lead-acid. The chemistry is more reversible. Degradation per cycle is much lower. Weight drops by two thirds. Usable capacity percentage is higher. Charging is faster. Voltage stays stable throughout discharge instead of sagging as the battery empties.

Price kept lithium out of reach for years. A quality pack used to cost more than some used golf carts. Nobody could justify that for a vehicle that hauls golf clubs around a course. Then manufacturing scaled and Chinese production matured. Prices dropped hard. A decent lithium pack now costs roughly double what flooded lead-acid costs, and that gap keeps shrinking.

Lithium iron phosphate, usually abbreviated LFP or LiFePO4, is the type used in golf carts. Other lithium chemistries power phones and laptops and electric cars. Those chemistries pack more energy into less weight but they're less stable. The lithium batteries that catch fire in the news are usually cobalt-based chemistries pushed too hard. Iron phosphate is more forgiving. It tolerates abuse better and doesn't catch fire under normal failure modes. Anyone selling non-iron-phosphate lithium batteries for golf cart use is prioritizing specs over safety.

The weight difference is immediately obvious. Lead-acid packs weigh three to four hundred pounds total. Lithium packs weigh under a hundred pounds for equivalent usable capacity. The cart accelerates faster, stops shorter, handles better, and uses less energy moving itself around. Tires and suspension components wear slower because they carry less mass.

The first time driving a lithium-converted cart feels strange. The cart responds quicker than expected because the motor moves less weight. Braking feels more confident. Corners feel more stable. The improvement is noticeable immediately and doesn't fade after getting used to it. Going back to a lead-acid cart afterward feels sluggish by comparison.

Cycle life buries lead-acid. Quality lithium cells last thousands of cycles. Flooded lead-acid lasts hundreds of cycles under real-world conditions with typical owner maintenance. A single lithium pack can outlast three or four sets of lead-acid batteries. For anyone keeping a cart more than five years, lithium often costs less in total despite the higher purchase price.

Usable capacity comparisons mislead buyers who only look at amp-hour ratings. Lead-acid batteries shouldn't discharge more than half their rated capacity to avoid accelerated wear. Lithium batteries safely discharge eighty percent or more. A lithium pack with a smaller number on the label often delivers more usable energy than a lead-acid pack with a bigger number. Spec sheets don't explain this, so buyers compare numbers that don't mean the same thing.

Voltage behavior differs throughout discharge. Lead-acid voltage drops progressively as the battery empties. A full 48-volt pack reads over fifty volts. Near empty it reads in the low forties. Motor power drops correspondingly. The cart slows down noticeably toward the end of a charge. Lithium holds voltage steady until nearly empty, then drops fast. Performance stays consistent across the whole discharge range. The cart drives the same on the last hole as the first.

Charging speed creates flexibility. Lead-acid needs eight to twelve hours for full charge. Lithium can charge in a couple hours. Plugging in during lunch adds meaningful range. Running multiple sessions per day becomes practical without spare battery sets.

Cold weather charging is the one real limitation. Charging lithium below freezing damages cells permanently. The chemistry doesn't reverse cleanly when cold. Quality packs refuse to charge when cold to prevent this. The cart can still discharge in cold weather without harm, just can't recharge until warmed up. This matters for winter storage in unheated spaces. Either store the cart somewhere above freezing or accept that it won't charge until spring.

The battery management system inside every lithium pack monitors cells and protects against overcharge, overdischarge, and overtemperature. BMS quality varies more than cell quality across different brands. Premium packs use active balancing that transfers energy between cells to keep them matched. Budget packs use passive balancing that bleeds energy as waste heat. Active balancing preserves more of the energy you paid for. Passive balancing works but less efficiently. The difference affects long-term reliability more than initial performance.

Battle Born, RELiON, and Dakota Lithium have established track records with responsive warranty support. These companies have been around for years and answer the phone when something goes wrong. Ampere Time and Vatrer offer decent quality at lower prices. SOK and Lossigy compete on price with acceptable but basic BMS implementations. Unknown brands priced far below market rates often use rejected cells and minimal protection electronics. Initial testing looks fine. Problems appear after the return window closes.

The cheap lithium market has a specific failure pattern. A brand nobody has heard of appears on Amazon or Alibaba selling packs at half the price of established names. Reviews are sparse but positive. The specs look identical to premium brands. Buyers figure it's all the same Chinese cells inside anyway, so why pay more.

What's different is which cells go in which packs. Cell manufacturers sort their production into grades. The best cells with consistent capacity and low internal resistance go to premium customers. Lesser cells go to whoever will buy them cheap. The worst cells get rejected. Budget battery assemblers buy those rejected cells because the price is right. The BMS might be adequate or might be minimal. Quality control might exist or might not.

These packs work for a while. The cells hold charge and deliver current. After a year or two, the weaker cells start failing. The BMS may or may not handle this gracefully. Some packs shut down safely. Others catch fire. The Amazon seller has either disappeared or refuses returns outside the original window. The warranty, if any existed, is unenforceable. The buyer who saved eight hundred dollars on batteries now needs new batteries anyway.

Spending the extra money on established brands buys insurance against this failure mode. Not guaranteed insurance—any company can have quality issues—but better odds. The premium includes warranty support that actually exists when needed.

How long you keep the cart changes everything about cost. Keeping a cart less than three years favors whatever is already installed or whatever is cheapest. Keeping a cart more than five years usually favors lithium even when purchase price runs higher. The three to five year range is murky and depends on the specific prices and usage.

Converting to Lithium

Swapping from lead-acid to lithium isn't just a battery swap. Other things change too.

Weight distribution shifts when you remove three hundred pounds from the battery compartment. The cart sits and handles differently. Some carts ride higher. Some feel front-heavy or rear-heavy depending on original weight placement. Quality conversion kits include mounting hardware that positions the lighter lithium pack appropriately. Budget conversions using improvised mounting sometimes create handling problems.

The ride height change affects more than aesthetics. Carts designed for lead-acid weight have the suspension geometry set up for that load. Remove the weight and the suspension sits at a different point in its travel. Spring rates feel different. Bump absorption changes. Most owners don't notice or don't care. Some find the handling worse after conversion and don't understand why.

The fuel gauge stops reading correctly. Stock gauges measure voltage and translate that into a battery level indicator. Lead-acid voltage drops steadily as the battery empties, so the gauge needle drops steadily too. Lithium voltage holds flat until nearly empty, so the gauge reads full right up until the cart dies. Either replace the gauge with a lithium-specific unit, recalibrate the existing gauge if possible, or use a pack with its own display built in.

Running out of charge becomes more sudden with lithium. Lead-acid gives warning. The cart slows down. Hill climbing gets weak. There's time to limp home. Lithium holds voltage until it doesn't. The cart runs fine, then the BMS cuts power to protect the cells, then the cart stops. Middle of the fairway, middle of the neighborhood, wherever. No warning, no limp mode.

Charger compatibility matters less than with AGM because most lithium packs include their own charging circuitry. Just plug them into standard power and the internal electronics handle the rest. Some packs require an external lithium charger. Check before buying.

Wiring should be inspected during conversion. Lead-acid corrosion and wear accumulate over years. Starting fresh with lithium makes sense when the wiring is already questionable. Loose or corroded connections increase resistance. Increased resistance causes heat. Heat accelerates problems. Bad wiring can cause fires regardless of battery type.

The motor controller might need attention too. Controllers designed for lead-acid voltage sag might behave differently with lithium's stable voltage. Most work fine. Some run the motor harder than intended because they expect voltage droop that doesn't happen. Hot motors, shortened motor life, and in rare cases controller failure can result. High-performance lithium conversions sometimes include controller upgrades.

Picking Batteries

The battery decision comes down to three questions. How long will the cart be kept? How honestly do maintenance commitments translate to actual behavior? What is the realistic budget?

Short ownership periods favor cheapest upfront cost. No point investing in longevity for a cart being sold soon. Flooded lead-acid works fine if someone else inherits the maintenance burden or replacement cost. Dumping money into lithium before selling makes no sense financially.

Medium ownership periods require honest self-assessment. Buyers who actually maintain equipment can run flooded batteries successfully. Buyers who let maintenance slide should pay extra for AGM or lithium to avoid the consequences of their own neglect. The question isn't whether someone intends to maintain batteries properly. The question is whether they actually will based on past behavior with other equipment.

Long ownership periods favor lithium for most buyers. The higher purchase price amortizes over more years. Zero maintenance eliminates the discipline question. Total cost often runs lower than lead-acid alternatives when multiple replacement cycles factor in.

The industry is moving toward lithium as standard. Club Car, E-Z-GO, and Yamaha all offer lithium options on new models. Some configurations come with lithium as the only choice. The aftermarket conversion business has grown substantially. Lead-acid will remain available for years because the installed base of older carts ensures demand, but development investment has shifted.

Buyers deciding today are choosing between technologies on different trajectories. Lead-acid is mature, well-understood, and not getting better. Lithium continues improving while prices fall. The direction is clear even if the timing of full transition remains uncertain.