How to Dispose of a Lithium Battery?

The lithium battery disposal question appears deceptively simple on the surface: what should be done with an old laptop battery? The answer, unfortunately, is not simple at all. The lithium battery in a smartphone holds enough energy to power a small LED for weeks—and enough chemical potential to ignite a fire capable of melting steel. This duality defines the central challenge of modern portable energy storage: the very properties that make lithium-ion cells revolutionary also render them uniquely dangerous when their lifecycle ends.

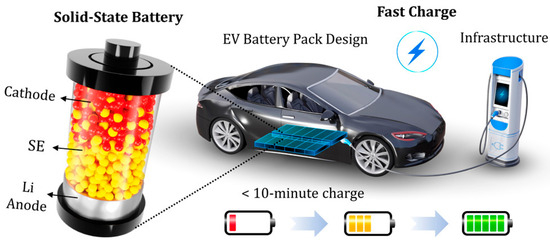

Modern lithium-ion batteries power everything from smartphones to electric vehicles, creating an unprecedented disposal challenge.

The data presents a sobering reality: according to the IEA's Global EV Outlook 2023 report (page 142, for verification), approximately 800,000 metric tons of lithium-ion batteries reached end-of-life globally last year. By 2030, their projections put that number somewhere between 2.4 and 4.7 million metric tons—the range is huge because nobody really knows how long EV batteries will last in real-world conditions. The variables include climate, charging habits, driving patterns, and manufacturing quality variations that remain difficult to model accurately. What the data confirms is that the infrastructure to handle even current volumes doesn't exist. Not even close. What happens to these batteries—whether they enter legitimate recycling streams, languish in warehouse corners, or detonate inside garbage trucks—will shape public health outcomes, resource security, and industrial safety for decades to come.

Before You Begin: Understanding the Stakes

Consumer behavior data reveals a disturbing pattern: approximately one-third of households discard lithium-ion batteries directly into household trash, while another third deposit them into curbside recycling bins alongside aluminum cans and cardboard. Both actions constitute dangerous mistakes with consequences extending far beyond individual households. The perception that small batteries pose minimal risk has proven catastrophically incorrect across hundreds of documented incidents.

A tour of a materials recovery facility in Phoenix—one of the larger ones in the Southwest—reveals the scale of the problem. The operations manager, a professional with 22 years in waste management, maintains detailed incident logs. In 2023 alone, that single facility recorded 34 fires linked to lithium batteries. Thirty-four. At one facility. Multiply this across thousands of waste processing centers nationwide, and the scope of the crisis becomes apparent.

The Fire Problem

Materials recovery facilities face increasing fire risks from improperly disposed lithium batteries.

The Fire Protection Research Foundation published a report in 2020 titled "Lithium-Ion Battery Hazards and Use Assessment" (available on their website, FPRF.org) that documented 245 waste facility fires across 28 states between 2016 and 2022. This figure represents only verified incidents at facilities with adequate investigation resources and documentation protocols. The National Waste and Recycling Association claims the real number is around 5,000 annually—roughly fourteen per day across the United States alone. Industry groups push back hard on this figure, arguing it counts any fire where a lithium battery was found in the debris, regardless of whether it actually caused the ignition. Fire investigators on both sides suggest the truth is somewhere in the middle—probably 1,500 to 2,000 genuine lithium battery fires per year. Still a massive number. Each incident carries a median damage cost exceeding $250,000, with catastrophic events reaching tens of millions in property damage, remediation costs, and operational disruption.

"The separator membrane inside a lithium cell is about 20-25 microns thick—roughly a quarter the width of a human hair. This impossibly thin barrier represents the only physical obstacle between stable energy storage and violent discharge."

The mechanism is thermal runaway, and understanding it properly changes how these batteries should be handled. The separator membrane inside a lithium cell is about 20-25 microns thick—roughly a quarter the width of a human hair. This impossibly thin barrier represents the only physical obstacle between stable energy storage and violent discharge. During normal operation, lithium ions migrate through an electrolyte solution between anode and cathode, with this permeable membrane maintaining necessary separation. Physical damage—crushing, puncturing, or even extreme pressure—can breach this separator. When cathode and anode touch, the result is a short circuit that converts chemical energy to heat almost instantaneously. This heat triggers exothermic decomposition of the cathode material, releasing oxygen that feeds further combustion.

Dr. Judy Jeevarajan, who ran the battery safety lab at Underwriters Laboratories before moving to the private sector, has documented temperature spikes that can hit 1,500°F within 4-6 seconds. Her team measured peak temperatures around 4,900°F in worst-case scenarios—hot enough to melt aluminum and ignite adjacent materials regardless of their nominal fire resistance. The speed of this escalation leaves virtually no time for intervention once thermal runaway initiates.

Now consider that battery inside a garbage truck compactor generating 2,000+ PSI of crushing force. A single improperly discarded laptop battery, subjected to such force, becomes an incendiary device of considerable power. The resulting fire occurs inside an enclosed metal container filled with paper, cardboard, and plastic—ideal accelerants that transform a chemical reaction into a conflagration. Drivers have been injured, some severely. Trucks have been destroyed, representing losses of $300,000 or more per vehicle. In several documented cases, fires spread to adjacent structures before suppression crews could intervene, causing damage to businesses and residences that had no connection to the original waste stream.

The Resource Problem

This part doesn't make headlines, but it matters more in the long run. Beyond immediate safety concerns lies a slower-moving but equally consequential crisis: resource depletion and the environmental toll of extraction.

The USGS Mineral Commodity Summaries 2024 (pages 52-53) reports that the Democratic Republic of Congo produced 170,000 metric tons of cobalt in 2023—roughly 73% of global supply. Amnesty International reports document conditions in artisanal mines, including instances of child labor, inadequate safety equipment, tunnel collapses, and wages that fail to meet basic subsistence needs. Satellite imagery shows the scale of lithium extraction operations in Chile's Atacama, where evaporation ponds consume water resources critical to indigenous communities and fragile desert ecosystems that have existed in delicate balance for millennia.

The demand trajectory for these materials admits no ambiguity. Electric vehicle adoption continues accelerating globally, driven by government mandates, improving economics, and consumer preference shifts. Each EV battery pack contains kilograms of lithium, cobalt, nickel, and manganese—materials that required significant environmental and human cost to extract and refine. When a battery goes into a landfill, everything extracted to make it—everything that disrupted ecosystems and communities to obtain—gets buried permanently. The molecular bonds remain intact but inaccessible, locked beneath layers of refuse for geological timescales.

Grand View Research valued the lithium-ion battery recycling market at $7.3 billion in 2024 (Report ID: GVR-1-68038-797-2). They're projecting 22.8% CAGR through 2030, growth rates that reflect urgent market recognition of an elementary truth. Those aren't speculative numbers—that's money flowing into an industry because the economics finally work. The cobalt concentration in a spent laptop battery runs around 5-15% by weight. The richest natural cobalt ore deposits on Earth average maybe 0.3%. Urban mining of spent batteries—recovering materials from discarded cells rather than extracting virgin resources—will become essential to maintaining industrial civilization as primary deposits deplete and extraction costs rise.

Identifying Your Battery Type

Proper disposal begins with accurate identification. Battery misidentification causes real problems at recycling facilities, making proper identification essential before any disposal attempt. Lithium batteries divide into two fundamental categories with distinct hazard profiles and recycling pathways.

Rechargeable Lithium-Ion (Li-ion, LiPo)

These cells dominate portable electronics and have achieved near-total market penetration in consumer devices. They use lithium compounds at the cathode—typically lithium cobalt oxide, lithium iron phosphate, or lithium nickel manganese cobalt oxide—and graphite at the anode, with a flammable organic electrolyte facilitating ion transfer.

Phones, laptops, tablets, power tools, e-bikes, drones, cordless vacuums, e-readers, and increasingly medical devices and residential solar storage systems—all lithium-ion. The chemistry delivers exceptional energy density and rechargeability but presents fire risks when damaged or improperly handled.

Non-Rechargeable Lithium Metal

These batteries use actual metallic lithium at the anode rather than lithium compounds. This chemistry delivers exceptional energy density and shelf life measured in decades, making these cells ubiquitous in applications demanding long-term reliability without maintenance.

Coin cells in watches, button cells in hearing aids, the battery in smoke detectors that lasts ten years, automotive key fobs, military equipment, and industrial sensors. These carry UN3090 classification and have different disposal requirements due to the heightened reactivity of metallic lithium.

This distinction matters because lithium metal coin cells frequently end up in Li-ion collection bins by mistake. The recycling processes are completely different—hydrometallurgical extraction for lithium-ion cells, specialized approaches for lithium metal—and contamination reduces recovery efficiency while potentially introducing hazardous byproducts.

Most casings are marked with chemistry notations: "Li-ion," "Lithium Ion," "LiPo" (lithium polymer), or the standard recycling symbol with chemistry designation. For unmarked batteries, the manufacturer's website will have specs searchable by model number. Device manuals specify battery type for embedded cells lacking external markings. The thirty seconds spent checking prevents downstream problems that can affect entire recycling batches.

Preparing Batteries for Storage and Transport

The interval between when a battery is removed and when it reaches a drop-off location is when most incidents happen. Proper preparation prevents the short circuits that initiate thermal runaway during storage and transport, transforming dangerous materials into manageable ones.

Proper terminal protection is essential for safe battery storage and transport.

Lithium batteries store tremendous energy in compact form factors. Two terminals separated by millimeters represent the only barrier between stable storage and catastrophic discharge. Any conductive material bridging these terminals—a stray paper clip, another battery's casing, a metal shelf, loose change, keys—completes the circuit. The resulting current flow generates heat proportional to the resistance of the bridging material, potentially igniting the electrolyte within seconds.

One documented case involved collected batteries stored in a metal coffee can in a residential garage. Two batteries shifted, terminals touched the can's interior, and half the garage was lost to fire. The homeowner had believed the collection container was helping—an attempt at responsible disposal that instead created the conditions for disaster.

Tape the terminals. The EPA has been recommending this for years, and it works. Electrical tape, masking tape, packing tape—anything non-conductive that creates a physical barrier over exposed metal contacts. For cylindrical cells like those found in power tools and flashlights, wrap both ends to cover the positive button terminal and negative flat terminal. For coin cells, cover both flat faces completely. For pouch cells (the flat flexible ones common in tablets and slim laptops), tape over the exposed foil tabs at the edge where electrical connections are made. For prismatic cells with multiple visible terminals, ensure all connection points are covered.

About swollen batteries: if bulging is visible, the cell has already begun to fail. The characteristic swelling results from gas generation inside the cell—typically from electrolyte decomposition or lithium plating on the anode. These gases indicate ongoing chemical reactions that may accelerate without warning. If the battery is not actively smoking, hissing, or hot to the touch, place it immediately in a ziplock bag, then in a rigid plastic container with a secure lid, then move that container somewhere with concrete flooring—a garage or patio, away from flammable materials and living spaces. Do not place it in a vehicle where temperatures can spike dramatically. Do not place it inside a residence where a fire could trap occupants. Call the manufacturer and the local hazardous waste program before attempting transport; damaged batteries require specialized handling that exceeds standard drop-off protocols.

If the battery is hot, making noise, or producing visible vapor: evacuate immediately and call 911. This is not an exaggeration. The time between visible off-gassing and ignition can be seconds. Do not attempt to move or contain such a battery. Do not attempt to extinguish a lithium battery fire with water, which can intensify the reaction. Professional emergency responders have training and equipment for these scenarios.

Store collected batteries awaiting disposal at room temperature, avoiding exposure to direct sunlight, heat sources, or freezing conditions. A car dashboard in summer can reach 170°F—well above the temperature threshold where damaged cells may enter thermal runaway. Use dedicated plastic containers, never metal. Label containers clearly so that household members understand the contents and associated precautions.

Finding Legitimate Disposal Options

This section warrants particular attention, because significant variation exists in the quality of disposal options available. The legitimacy of a disposal channel determines whether batteries enter genuine recycling streams or merely transfer to less regulated handlers. This matters more than most consumers realize.

Call2Recycle (call2recycle.org/locator) is the largest nonprofit battery recycler in North America, maintaining drop-off locations at major retailers nationwide. Their locator tool identifies participating stores within specified radius. They operate drop-off points at most Home Depot and Lowe's locations, many Best Buy and Staples stores, and some Target and Walmart locations depending on region. Auto parts stores like AutoZone and O'Reilly take automotive batteries, including the large lithium packs increasingly found in hybrid and electric vehicles. Most counties operate a household hazardous waste facility accepting lithium batteries without charge—search "[county name] household hazardous waste" for schedules, which are often limited to weekends or monthly events. Some facilities maintain daily hours while others offer only periodic collection events, so advance research prevents wasted trips.

Major electronics manufacturers operate battery return programs with varying degrees of accessibility. Apple, Dell, HP, Samsung, and most major brands offer take-back options, often with prepaid shipping labels for direct-to-recycler transport. These programs represent the most direct path from consumer to legitimate processing.

An important industry reality requires attention: the battery recycling industry includes both genuine processors and middlemen who collect batteries and flip them to whoever pays most. Batteries collected by uncertified handlers sometimes end up exported to countries with minimal environmental oversight, where processing occurs under conditions that would violate regulations in developed nations. Inspectors have traced e-waste shipments labeled as "used electronics for refurbishment" to facilities in Southeast Asia that were basically open-air burning operations, releasing toxic compounds into air and water while recovering only the most valuable materials and discarding the rest.

Legitimate recyclers hold R2 or e-Stewards certification, third-party verified standards that require documented chain of custody and environmentally responsible processing. They publish their processes openly. They don't charge fees for household quantities, as material value covers processing costs. They can explain exactly what happens to materials after they leave the drop-off point—which facilities process which streams, what recovery rates they achieve, where outputs go. These questions should be asked before dropping anything off. Evasive answers or requests for payment for small quantities suggest intermediaries rather than processors.

Transport and Drop-Off

Place taped batteries in a rigid plastic container with a secure lid. Place that container in the vehicle trunk or cargo area, away from the passenger compartment and secured so it won't slide around during transit. Loose batteries shifting during transport can contact each other despite terminal taping; container walls provide additional isolation. Complete the drop-off the same day—batteries should not sit in a car that might hit 140°F on a summer afternoon, as elevated temperatures increase the risk of thermal events in compromised cells.

For anything over 25 pounds, DOT regulations apply. The Department of Transportation has specific requirements for identification, packaging, and labeling of lithium battery shipments. The "Check the Box" campaign (checkthebox.dot.gov) explains compliant packaging for larger shipments and helps shippers understand their obligations under hazardous materials regulations.

Arrive during facility operating hours—many household hazardous waste sites maintain limited schedules, often weekend-only or appointment-based. Bring identification if required by local policy. Inform staff about battery types and condition, specifically noting any damaged units requiring special handling. Follow facility-specific instructions; some require batteries remain in personal containers while others provide collection bins with specific placement protocols. Request a receipt or certificate of recycling for documentation purposes.

E-bike batteries often exceed 500 watt-hours and require specialized handling for disposal.

E-bike and e-scooter batteries deserve special mention because they're large enough to cause serious incidents. These large-format lithium batteries often exceed 500 watt-hours—energy equivalent to hundreds of smartphone batteries in a single pack. Most household hazardous waste facilities require appointments for batteries over 500 watt-hours due to the specialized handling required. Call2Recycle runs a dedicated e-bike program (call2recycle.org/e-bikes) specifically addressing these high-capacity packs.

For damaged, defective, or recalled batteries, Call2Recycle sells specialty containment kits—about $75-100—engineered to contain thermal events during transport. These provide DOT-compliant fire-resistant packaging designed to suppress ignition during transit. For a swelling or damaged battery from an EV or e-bike, this is the appropriate solution. Organizations generating significant battery waste should establish accounts with certified recyclers offering scheduled pickup services, removing transport burden while ensuring proper chain of custody.

Making Batteries Last Longer

The most effective intervention is reducing the need for battery disposal. The highest-impact strategy is not better disposal but reduced disposal frequency through extended battery lifespan.

Lithium-ion cell longevity depends heavily on operating conditions. Battery degradation studies consistently support the following practices: keep charge between 20-80% when possible, as both full discharge and full charge stress the electrode materials and accelerate capacity fade. Avoid fast charging unless necessary, as rapid charging generates heat that accelerates electrolyte decomposition and promotes lithium plating on the anode. Don't leave devices in hot cars, where temperatures can exceed safe operating ranges within minutes. Store devices long-term at around 50% charge, the state that minimizes stress on cell chemistry during extended inactivity. Update device firmware regularly to benefit from power management improvements that manufacturers release based on field data. These practices can extend lithium-ion lifespan by 2-3x, delaying replacement cycles and reducing total battery consumption over time.

The second-life market is growing as industry recognizes that retirement from primary applications doesn't mean end of useful life. Batteries retired from EVs at 70-80% capacity—insufficient for vehicles demanding consistent performance under varying loads—work fine for stationary storage applications where weight and space constraints matter less. Backup power systems, grid stabilization, and low-drain electronics can utilize cells that no longer meet automotive specifications. Companies like Cirba Solutions and Battery Resourcers evaluate packs for repurposing potential before recycling, extracting maximum value from each manufactured unit.

On regulations: the European Battery Regulation will require user-replaceable batteries in all portable devices by 2027, a mandate that will reshape device design globally as manufacturers adapt products for international markets. California, Washington, and New York have implemented extended producer responsibility laws requiring manufacturers to fund collection and recycling infrastructure, shifting costs from municipalities and consumers to companies profiting from battery sales. More states are following with similar legislation under consideration. The landscape is shifting, slowly but measurably, toward systems that account for full lifecycle costs rather than externalizing disposal burdens.

Under existing federal regulations, businesses generating lithium battery waste should consider managing all used cells under universal waste regulations codified in 40 CFR Part 273, which provides a streamlined framework for accumulation and transport. Consultation with environmental compliance specialists can clarify specific obligations based on waste volumes and operational scope, ensuring legal compliance while minimizing administrative burden.

That covers the practical for lithium battery disposal. The bigger picture—whether recycling capacity is being built fast enough to handle the tsunami of batteries coming from EV retirements in the 2030s—is a question that defies easy answers. Current infrastructure handles a fraction of existing volumes; scaling to meet projected demand requires investment, policy support, and technological advancement that remain uncertain. What the evidence confirms is that every battery that enters a legitimate recycling stream instead of a garbage truck makes a small difference. Enough small differences might add up to something meaningful for resource security, environmental protection, and public safety in the decades ahead.