In my opinion outdoor installation is burning money.

Not that outdoor is impossible. It works. But most outdoor installations are slowly killing their batteries, and cutting the lifespan in half is getting off easy. The reason is simple. Nobody wants to spend what outdoor installation actually costs.

The Charging Temperature Thing

Discharge temperature is forgiving. Lithium cells work from -20°C to 60°C. Cold means lower capacity, heat means faster aging, but the battery functions.

Charging is different. Below 0°C, lithium ions cannot insert into the graphite structure. They deposit directly on the surface as metallic lithium. This metallic lithium never converts back to usable capacity. One charge event, one round of damage, irreversible.

Winter morning solar charging presents unique challenges for outdoor battery systems

The solar system problem: winter mornings, battery is coldest, sun just came up, generation is strongest, charger sees power and starts pushing. -5°C battery getting force-charged. Every morning. Damage accumulating.

BMS has low-temp protection? Sure. But when protection triggers, no charging happens. Wasting the best solar hours of the day.

Heating system? Most products ship with 60W heating pads. 100kg battery pack going from -15°C to 5°C with 60 watts. How long does that take? By the time the cells warm up, the sun is already setting.

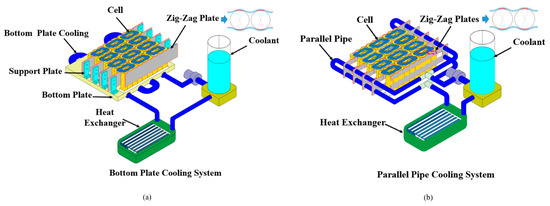

Powerwall uses liquid glycol heating. Actually works. Most competitors slap on two resistive strips and call it done.

Indoor? Garage at 5°C, normal charging, none of this nonsense.

Speaking of Powerwall, a quick rant about Tesla's closed system. Powerwall only works with Tesla's own Gateway. Gateway dies, your perfectly good battery becomes a brick. Unless you want to pay full price for another Gateway.

Enphase does the same thing. IQ batteries only work with Enphase microinverters.

People who buy these closed systems, five years later when something breaks out of warranty, they learn what lock-in really means. Victron, Sol-Ark, open protocol products, configuration is more annoying, but at least when one component dies you replace that one component, not the whole system.

Got sidetracked there.

IP Ratings Are a Joke

IP65, protected against water jets, sounds impressive.

Test method: 6.3mm nozzle, 3 meter distance, 12.5 liters per minute, spray for 3 minutes, no water ingress means pass.

3 minutes.

Outdoor environment does not attack for 3 minutes. It attacks for 10 years.

Cable gland seals rely on rubber compression. UV hardens the rubber. Compression force disappears. Water starts getting in year 3, year 4, long after warranty inspections end.

Temperature swing is worse. 40°C daytime, 10°C nighttime. The enclosure expands and contracts like it's breathing. Pulls in humid air during the day, condenses it into water droplets at night. Day after day. Month after month.

Coastal is brutal. Salt fog does not need bulk water entry. Seeps through tiny gaps, crystallizes on PCB, creates conductive bridges where there should not be any. BMS readings go haywire. Protection circuits trip for no apparent reason. Impossible to diagnose.

Growatt ARK series. IP65. Plastic enclosure. Gaskets harden within 2 years. BYD Battery-Box, steel enclosure, better, but their own installation manual says exposed mounting needs a rain cover. This information does not appear on marketing materials.

Humidity, the Invisible Killer

Water vapor reacts with LiPF6 in the electrolyte to form hydrofluoric acid. HF corrodes electrodes and current collectors.

The scary part: early symptoms are rising internal resistance, not capacity loss. Monitoring software shows capacity is fine. Meanwhile the battery is rotting inside. By the time capacity drops noticeably, internal resistance is already high enough to cause overheating during high-rate discharge.

Plastic enclosures cannot stop water vapor. HDPE transmits about 0.5 grams per square meter per day at 38°C and 90% humidity. Does not sound like much. What about over 10 years?

Metal enclosures are much better. SimpliPhi uses aluminum. Fortress uses steel. Cheap Chinese imports are mostly injection-molded plastic.

Air-conditioned room: 40-60% humidity. Tropical outdoor: 90%+ humidity for months at a time.

What Actually Goes Wrong

The failure modes repeat. Same mistakes, thousands of installations.

Connector corrosion is number one. MC4 connectors use spring-loaded contacts. Tight metal-to-metal fit. Moisture gets in, oxidation forms, resistance increases. Connection heats up under load. Heat speeds up oxidation. Eventually arc flash, melted plastic, fire hazard.

Proper electrical connections and quality components are critical for long-term reliability

Torque specs exist for a reason. Battery terminal bolts need specific torque, usually 8-12 Nm. Installers in a hurry use impact drivers. Under-torque means connection loosens over thermal cycles. Over-torque cracks the insulator or strips threads. Both lead to high-resistance connections that heat up and eventually fail.

Rodents. Nobody talks about this, but outdoor enclosures with gaps over 6mm invite mice. They nest in warm spaces during cold weather. They chew wire insulation to keep their teeth sharp. One mouse can destroy a wiring harness in one night. Powerwall 2 uses a sealed enclosure, no gaps. Most competing products have louvered vents. Guess which ones have rodent problems.

Ground faults accumulate slowly. Outdoor wiring takes UV damage, abrasion, thermal stress. Each small insulation defect allows tiny leakage current to ground. Individual faults below detection threshold. Over years they add up. System starts tripping ground fault protection randomly. Or worse, operates with undetected ground current that creates shock hazard.

Conduit traps water. Horizontal runs without drainage. Water collects. Winter comes, freeze-thaw cracks fittings. Crack admits more water. Repeat until conduit is full. Connections designed for dry mounting end up submerged.

Indoor installation avoids most of this by default. Stable temperature means no thermal cycling damage. Climate control means no condensation. Enclosed space means no mice. Short wire runs stay dry.

Climate Zones

Battery behavior changes dramatically by geography. Manufacturers publish specs for 25°C because that temperature makes the numbers look good. Real installations almost never average 25°C.

Phoenix, Las Vegas, summer average 35°C. Outdoor batteries without active cooling hit internal temps of 45-50°C during afternoon discharge. At those temperatures LiFePO4 cycle life drops by roughly half compared to 25°C. NMC drops even faster. The 10-year warranty assumes conditions Arizona summer never provides.

Minnesota, Wisconsin, cold snaps drop to -30°C. Batteries without heating cannot charge at all. Batteries with weak heating keep cells barely above freezing while burning stored energy just to stay warm. A system delivering 10 kWh usable in July might deliver 6 kWh in January after heating overhead and limited charging windows.

Coastal Florida combines heat, humidity, and salt air. Each factor alone causes problems. Combined, they accelerate every degradation mechanism at once. Outdoor battery within 1 km of Florida coast is the worst environment for energy storage in the continental US. Indoor with dehumidification becomes almost mandatory.

Pacific Northwest is close to ideal. Seattle averages 11°C annually. Mild humidity. Minimal temperature extremes. Outdoor batteries there approach laboratory performance. Same product that struggles in Phoenix thrives in Portland.

Altitude matters for cooling. Denver at 1600m has 17% less air density than sea level. Fans move less mass per revolution. Heat sinks have lower convective efficiency. Active cooling systems designed for sea level underperform at altitude. Passive cooling degrades more gracefully.

Installers in mild climates dismiss thermal management as unnecessary expense. When they move to harsh climates or sell to customers who relocate, the same casual approach creates early failures. What works in San Diego does not work in Tucson.

BMS Quality

Every BMS datasheet lists the same protections. Overvoltage, undervoltage, overcurrent, overtemperature, short circuit. Numbers look similar across price ranges. $200 BMS and $2000 BMS both claim 100A continuous and 4.2V cutoff.

Difference is in implementation details no datasheet shows.

Cheap BMS samples cell voltages one at a time through a multiplexer. Accuracy degrades as multiplexer ages. Cells drift out of balance because BMS cannot detect millivolt differences.

Quality BMS uses simultaneous sampling with separate ADC per cell group. Accuracy stays stable over 10 years.

Cheap BMS triggers protection and hopes load disconnects gracefully. Quality BMS talks to inverter through CAN bus, requests controlled power reduction before hitting hard cutoff.

JKBMS units under $150 work fine for low-power applications. Push them to rated limits and thermal management weakness shows up as nuisance trips. Batrium costs 10x more, handles full rated current indefinitely.

For pre-built residential systems, BMS quality hides inside the enclosure. Evaluating it means asking questions manufacturers prefer to dodge. What sampling method? What balancing current? What communication protocols? What thermal derating curve? Vague answers mean commodity parts.

A lot of people think indoor installation requires ventilation planning. This is leftover thinking from lead-acid days.

Lead-acid releases hydrogen when charging. Needs ventilation. LiFePO4 releases no gases during normal operation. Gas release only happens during thermal runaway, and LiFePO4 thermal runaway requires temperatures above 270°C. Normal use never gets there.

A 10 kWh battery discharging at 1C produces maybe 100-200W of heat. Same as a small space heater. Natural convection in a regular room handles it.

Some building departments still demand battery room ventilation based on codes written for lead-acid. They have not updated their regulations. Bring manufacturer documentation showing zero gas evolution during normal operation. Usually resolves the issue and saves a wasted HVAC expense.

NMC is a different story. NMC thermal runaway temperature is lower, and it releases flammable gases. But NMC should not be used for home storage anyway. More on that below.

Why Only LiFePO4

NMC has higher energy density. True. Electric vehicles care about this because weight affects range.

Stationary storage cares about what, exactly? A 100kg battery and a 70kg battery, both bolted to a wall, what difference does it make?

The NMC problem:

Thermal runaway starts around 150°C. During thermal runaway it releases oxygen. Feeds its own combustion. Fire cannot be suppressed. Fire department shows up, they just wait for it to burn out.

LiFePO4 needs 270°C+ for thermal runaway. Does not release oxygen. Catches fire, it is a regular fire. Can be extinguished.

This is not theoretical. The famous Victoria battery fire in Australia. Megapack. NMC cells. Burned for four days. Tesla switched later Megapacks to LiFePO4.

Cycle life too. NMC cycle life is very sensitive to temperature. 3000 cycles at 25°C. Maybe 1500 cycles at 35°C average. LiFePO4 degradation curve is much flatter.

So why do manufacturers still push NMC? Cell cost is lower. Profit margin is higher. They tell you about energy density benefits. They do not mention safety differences. If something happens, that is your problem.

Enphase uses LiFePO4. Tesla Powerwall uses NMC but adds liquid cooling to manage the heat. If the NMC product you are buying does not have active thermal management, you are gambling.

Installation Orientation

This part gets skipped in most guides, or they just say "avoid direct sunlight."

South wall (northern hemisphere) absorbs solar radiation all day. Wall surface temperature exceeds air temperature by 15-25°C. Battery mounted there is sitting on an oven.

West wall is worse. Afternoon sun hits when air temperature is already at daily peak. Double whammy.

North wall has no direct sunlight all year. Wall surface temperature equals or is lower than air temperature. Battery can radiate heat to the wall instead of absorbing heat from it.

East wall gets morning sun. Morning air temperature and solar intensity are both lower. Not a big deal.

So north wall is best, east wall is second, south wall is tolerable, west wall is worst.

Wall orientation significantly impacts thermal load on mounted battery systems

Australia's Clean Energy Council installation guidelines explicitly state north wall preference. Most installers in the US do not care. Mount wherever cable runs are shortest.

Does adding a shade cover help? A little. But shade covers block direct sunlight, not wall radiation. South wall with shade cover is still worse than north wall with nothing.

Cell Sourcing

Nobody wants to talk about this because talking about it does not help sellers.

A battery system is cells plus BMS plus enclosure. Cells determine performance. Everything else is packaging.

Cell manufacturers have tiers. CATL, BYD, EVE, CALB are first tier. Each has A-grade and B-grade. A-grade meets all specs. B-grade has minor issues, slightly low capacity or slightly high resistance. B-grade is 30-40% cheaper.

What cells are inside the battery system you are buying? If the brand does not say, you do not know.

A premium-looking product with polished marketing could have mystery B-grade cells inside. A janky-looking product from a factory with zero marketing budget could have CATL A-grade cells.

Asking "what cells are inside" should be standard practice.

EG4 publishes cell supplier information. Signature Solar provides cell datasheets on request. Many other brands, when asked, just say "premium lithium iron phosphate cells" or "automotive-grade cells." That answer is the same as no answer.

About cycle life, all the marketing is playing games.

"6000 cycles" comes from testing at 25°C constant temperature, 0.5C rate, 100% to 0% full cycles, rest periods between cycles. Laboratory conditions.

Your battery might run at 35°C average in summer, occasional 1C bursts, charged to 100% and baking in the sun every day. Under those conditions, 4000 cycles would be lucky.

The meaningful metric is throughput: how many kWh the battery will charge and discharge in its lifetime. 10 kWh battery, 6000 cycles, 80% DOD, theoretical throughput 48,000 kWh. Actual throughput might be 35,000 if you are lucky.

No manufacturer will tell you about throughput because the numbers look small. "6000 cycles" sounds impressive. "35,000 kWh throughput" sounds like 10 kWh per day only lasting 9.6 years. Less sexy.

Cost Calculation

Purchase price divided by nameplate capacity gives a "dollars per kWh" number. This number is meaningless.

What matters: total spending divided by actual usable throughput.

$5000 battery, 10 kWh capacity, actual throughput 35,000 kWh, cost per kWh $0.14.

$7500 battery, 15 kWh capacity, roasted and frozen outdoors, actual throughput only 30,000 kWh, cost per kWh $0.25.

The "cheaper" one costs 78% more.

True cost analysis must account for real-world throughput, not just nameplate specifications

Indoor installation reaches 80% of lab throughput normally. Outdoor installation without proper thermal management might only hit 50%. Same battery, different environment, different value.

Spending $1500 extra on proper installation beats saving $1500 buying cheaper equipment. But most people just look at the price tag.

Also, US ITC tax credit applies to total installation cost, not just equipment. Spend $1500 on mounting and protection, 30% credit gives $450 back. Actual extra cost is $1050, but the battery lasts years longer.

Warranty fine print matters. Most battery warranties exclude damage from "environmental factors" or "improper installation." Definitions are vague on purpose. Outdoor battery fails from humidity damage, claim denied. Manufacturer says environmental exposure. Customer says IP65 rating. Whoever has better lawyers wins.

Extended warranty from third parties? Premium price reveals what actuaries know about failure rates. High premium for outdoor installation means high expected failures. The insurance math does not lie even when marketing does.

Replacement labor adds up. Outdoor battery on a second-floor wall means scaffolding, permits, half a day of electrician time. Indoor battery in a garage means none of that. First replacement costs more than expected. Second replacement costs even more because inflation hits labor rates.

Home insurance is a minefield. Some carriers exclude battery storage entirely. Some cover indoor but not outdoor from fire claims. Some require specific certifications like UL 9540A that not every product has. Ask the insurance company before installing. Better than finding out after a claim gets denied.

SOC Habit

Here is something most people do wrong without knowing.

Charging to 100% every day kills batteries faster. Calendar aging accelerates at high state of charge. Cell stored at 100% ages roughly twice as fast as cell stored at 50%. Nothing to do with cycling. Just sitting there at full charge, degrading.

Standard solar setup charges the battery full during the day, drains it at night. Every afternoon the battery sits at 100% in peak heat. Two aging accelerators combined.

Setting charge limit to 80% or 90% helps. 10 kWh battery limited to 80% delivers 8 kWh usable. Not a huge sacrifice. Lifespan extends 30-40%.

SolarEdge Home Battery has this setting in the app. Generac PWRcell buries it in installer menus and defaults to 100%. Check if the product supports charge limiting before buying, not after installing.

Low SOC also causes damage but different mechanism. Anode potential rises, dissolves copper current collector. Do not leave batteries below 20% for extended periods.

Sweet spot for daily operation: 20% to 80%. For storage longer than a month: 40-60%. Avoid extremes.

The Parallel Trap

Capacity not enough, thinking about putting multiple batteries in parallel? Think twice.

Parallel batteries must have matched voltage or circulating current happens. Higher voltage unit discharges into lower voltage unit, bypassing the load, just spinning internally and generating heat.

New batteries from the same batch match well enough. After 3 years, aging rates differ, SOC calibration drifts. Both show 50% but one is actually 48% and the other is 53%. Circulating current starts.

Consumer BMS manages its own cells, has no visibility into parallel neighbors, cannot coordinate.

Two or three units in parallel, problems are minor. Above four, odds of significant mismatch are high.

One 20 kWh battery is cleaner than two 10 kWh batteries in parallel. Costs more. Way less hassle.

Final Thoughts

If indoor installation is possible, install indoors. Garage, basement, storage room, end of a hallway, anywhere is better than outdoors.

If outdoor installation is the only option, north wall, rain cover, proper sealing, annual gasket inspection. Do not expect IP65 to protect you for ten years.

When budget is tight, prioritize installation quality over capacity size. A well-installed small battery is worth more than a poorly-installed large one.

Batteries do not understand humans. They understand temperature, humidity, voltage, current. You give them one environment, they give you one level of performance. Indoor versus outdoor comes down to choosing whether physics works for you or against you.