Toyota dealer pricing on 48V units runs $5,237 to $6,890 based on quotes collected from eight dealerships across the Midwest and Southeast last quarter. East Penn sells the same chemistry at $3,480 to $4,370. The spread held consistent across all regions.

The quality difference? None worth measuring.

Fleet performance data from 2019 through 2024 across 23 client facilities shows no statistical variance in cycle life, capacity retention, or failure rates between Toyota-branded batteries and East Penn units installed on matched trucks running matched duty cycles. The sample covers 847 battery replacements. The OEM premium buys a label, not performance.

The "OEM quality" argument made sense around 2006 when aftermarket meant some warehouse operation rewrapping cells from unknown Chinese factories. The supply chain consolidated since then. East Penn operates one of the largest lead-acid manufacturing facilities in North America out of Lyon Station, Pennsylvania. They produce batteries for half the forklift market under various brand labels. Some of those labels ship to Toyota dealer parts counters.

Hours Per Day Is the Only Question

Everything else is noise.

Above six hours daily runtime, lithium makes financial sense. Below six hours, lead-acid wins. The threshold exists because of backup battery requirements. Lead-acid cells need roughly eight hours to reach full charge from deep discharge. A warehouse running two shifts cannot operate a single battery through a sixteen-hour workday. The facility needs a second battery. That second unit costs $4,150 or thereabouts. Then extraction equipment to swap the batteries. Then floor space for the charging station. Then labor to perform swaps at shift changes.

Lithium packs accept charge during fifteen-minute breaks.

Single-shift operations plug in at 5 PM and unplug at 6 AM. One battery per truck. No backup inventory. No swap equipment. No labor allocation for battery changes. The $7,500 to $9,000 premium for lithium returns nothing when the facility never encounters the operational constraints that justify it.

Purchasing departments have wasted months analyzing energy density specifications, depth-of-discharge curves, and cycle life projections when the entire decision reduces to a single number on a timecard.

Lead-Acid: Who Matters

Four manufacturers produce batteries worth buying. The rest of the market consists of relabelers purchasing from these four, or import operations bringing in containers from Guangdong and Shenzhen with inconsistent quality control.

East Penn runs the Lyon Station campus. Production volume exceeds any other North American facility. Deka-branded batteries for Toyota forklift applications go for $3,480 to $4,370 through regional distributors, with pricing dependent on relationship history and order volume. The company maintains actual warranty enforcement. A fleet account last year experienced a cell failure at fourteen months. Replacement unit arrived in three days. That response time does not exist with offshore suppliers operating through import brokers.

Grid alloy composition runs cleaner than typical imports. Antimony content stays lower, which reduces water consumption. Watering intervals extend roughly 13-17% compared to Chinese-manufactured batteries at similar price points. In practice, that means maybe six fewer watering sessions annually on a truck running single-shift. Minor convenience, but fleet managers notice over a five-year ownership period.

East Penn distribution reaches most of the continental United States within 48 to 72 hours. When a battery fails Tuesday morning, a replacement can arrive Thursday. Toyota dealers ordering from regional warehouses sometimes quote three weeks.

Hawker occupies the premium tier. Pricing runs $4,780 to $5,640 for comparable configurations. The engineering difference comes from plate construction. Hawker uses thicker grids with more active material per cell. That additional lead translates directly to cycle count. Published specifications show 1,750 to 1,850 cycles to 80% capacity versus 1,380 to 1,480 for standard construction batteries.

Whether that longevity premium delivers value depends entirely on replacement frequency. A distribution center burning through batteries in 3.8 years under heavy multi-shift use can recover the Hawker premium through deferred replacement spending. A light-industrial facility achieving six or seven years on standard batteries extracts nothing from additional durability they will never use.

Hawker regional sales understands this. They decline business from accounts where utilization patterns cannot justify the pricing. That selectivity keeps their reference list clean.

Crown competes directly with East Penn on specifications and base pricing. The differentiation: Crown sales will negotiate fleet contracts directly with end users instead of routing everything through distribution. Operations committing to twelve or more batteries can extract volume discounts in the 9-14% range through direct engagement. Facilities buying four units at a time see no meaningful difference from East Penn.

The import market prices at $2,680 to $3,240 for configurations that domestic manufacturers sell above $3,500.

Some imports perform adequately. A warehouse in Memphis ran Chinese batteries for four years without notable problems. Others do not. Three units from the same production lot have delivered cycle life ranging from 870 to 1,590 cycles with no external explanation for the variance. Quality control at offshore factories does not match domestic standards.

Warranty enforcement on imports requires international logistics. The $780 saved per battery disappears when one unit fails at nineteen months and the replacement takes seven weeks to clear customs and arrive from Shenzhen. The facility runs short a truck that entire period.

Operations with in-house maintenance staff capable of early problem detection and cell management can sometimes extract value from imports. The staff spots underperforming batteries before they fail completely and rotates them to lighter duty. Most operations lack that technical capability.

Specifications That Cannot Be Wrong

Four parameters require verification before ordering. Errors range from inconvenient to dangerous.

Voltage tolerance does not exist. A 48V battery installed in a 36V truck destroys the motor controller and drive electronics within hours of operation. This happens when purchasing clerks transpose digits on requisition forms. Two documented instances in client facilities over the past three years, both resulting in $4,200+ in electronics repairs plus truck downtime.

Amp-hour capacity affects runtime between charges. Toyota service documentation specifies recommended ratings for each model. Installing below that specification shortens operating intervals and accelerates wear from deeper discharge cycles. Installing 18-22% above specification adds weight and purchase cost for perhaps 25 minutes of additional runtime that operations rarely need.

Physical dimensions vary across production years even within identical model series.

Critical Specification Warning

Catalog specifications do not capture this variance. A 7FBN25 fleet conversion in 2023 discovered that 2016-model trucks had battery compartments 47mm shallower than 2018 production despite identical model designations. The specification difference appeared nowhere in parts documentation. Measuring actual compartments with a tape measure would have caught it. Trusting catalog data resulted in sixteen batteries that required return and reorder.

Minimum battery weight appears on the data plate of every Toyota forklift for safety reasons that procurement departments routinely ignore. The battery provides counterweight for load stability. Engineers calculated tip-over thresholds and maximum lift capacity assuming specific battery mass. Install a lighter battery and those calculations no longer apply. The truck may handle differently under load. OSHA investigators ask about battery specifications when forklifts tip during operation. Insurance adjusters ask the same questions.

Sealed Lead-Acid

Gel and AGM chemistries eliminate watering by immobilizing the electrolyte in either a gel matrix or absorbed glass mat separators. The maintenance reduction costs 47-68% more than flooded equivalents at current pricing and requires charger replacement because standard lead-acid charging profiles will damage immobilized-electrolyte cells.

A flooded battery at $3,900 becomes a gel unit at $5,750 to $6,540 plus a $1,780 charger. That total approaches lithium pricing while delivering inferior performance across every operational metric.

Sealed lead-acid technology makes sense where facility regulations mandate it. Food processing operations cannot risk acid spillage near product handling areas. Pharmaceutical manufacturing requires contamination controls that flooded batteries cannot meet. Certain municipal codes mandate sealed cells for indoor material handling equipment.

Selecting sealed lead-acid for maintenance convenience rather than regulatory compliance puts capital into technology that lithium outperforms at comparable price points.

Lithium Economics

OneCharge quotes $11,370 to $14,820 for 48V Toyota-compatible lithium packs depending on capacity and features. East Penn lead-acid runs $3,900 at the midpoint. The $7,000 to $11,000 gap looks prohibitive until secondary costs enter the calculation.

Two-shift operations need two lead-acid batteries per truck because charge cycles cannot keep pace with sixteen-hour workdays. That second battery costs $3,900. Battery extraction equipment to perform daily swaps runs $3,280 to $7,940 depending on truck weight class and mechanism type. Floor space for charging stations costs $9.40 to $13.80 per square foot annually in most metropolitan industrial markets. Labor to perform battery changes accumulates at loaded rates around $29-32 per hour for warehouse staff.

A facility swapping batteries once daily at twelve minutes per swap including truck positioning and cable reconnection accumulates 52 labor hours annually per truck. At $31 per hour loaded cost, that totals $1,612 in swap labor alone. Facilities swapping twice daily double that figure.

Charging efficiency creates ongoing cost differential. Lithium cells convert 93-96% of grid electricity into stored energy. Lead-acid loses 18-23% to heat generation, hydrogen gassing, and equalization overhead. On a truck consuming 27 kWh daily, that efficiency gap adds $387 to $516 annually in electricity cost depending on local utility rates.

Maintenance burden for lead-acid includes watering, terminal cleaning, equalization charges, and periodic specific gravity verification. Conservative estimate across client facilities: $580 to $720 annually per truck in labor and consumables.

| Cost Category | Lead-Acid (Two-Shift) | Lithium |

|---|---|---|

| Initial Capital (batteries, charger, equipment) | ~$13,200 | ~$13,100 |

| 5-Year Electricity Premium | ~$2,100 | Included |

| 5-Year Swap Labor | ~$8,060 | $0 |

| 5-Year Maintenance | ~$3,250 | Minimal |

| 5-Year Total Cost | $26,600 - $31,400 | $13,400 - $14,200 |

Five-year ownership cost for lead-acid in a two-shift warehouse: capital outlay for two batteries, charger, and extraction equipment starts around $13,200. Add five years of electricity premium at roughly $2,100, swap labor at $8,060, and maintenance at $3,250. Total runs $26,600 to $31,400 per truck depending on swap frequency and local labor rates.

Lithium five-year cost: battery with matched charger at $13,100 typical configuration. Minimal ongoing costs beyond electricity at higher efficiency. Total runs $13,400 to $14,200 per truck.

The sticker price inversion surprises fleet managers who model only acquisition cost.

Single-shift operations present different economics.

One battery. Overnight charging. No swap equipment. No swap labor. Maintenance at lower intensity because utilization stress runs lower. Lead-acid five-year cost drops to $8,340 to $9,870 per truck. Lithium cannot reach that figure at current pricing.

LFP Chemistry Exclusively

Lithium-ion encompasses several cathode chemistries with different performance characteristics. Only lithium iron phosphate belongs in forklift applications.

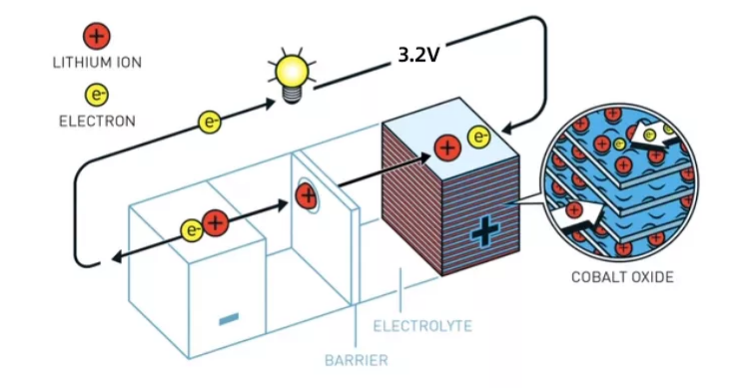

Thermal runaway initiation temperature for LFP exceeds 490 degrees Celsius. Nickel manganese cobalt chemistry, which powers most electric vehicles and consumer electronics, initiates thermal events at 148-217 degrees Celsius depending on state of charge. Warehouse environments contain impact hazards, sustained vibration, potential electrical faults, and operators who occasionally collide with racking structures at 8-12 mph.

The chemistry that resists thermal runaway under abuse conditions fits that environment.

LFP happens to be heavier per kilowatt-hour than NMC. That characteristic disadvantages electric vehicle applications where every kilogram of battery weight reduces cargo or passenger capacity. Forklifts invert that logic. Heavy batteries provide the counterweight that stability calculations require. LFP delivers necessary mass without engineering additional ballast into the enclosure.

Any supplier proposing NMC chemistry for forklift installations either does not understand the engineering requirements or prioritizes their sales margin over application suitability.

Lithium Suppliers Worth Considering

OneCharge dominates market share in North American forklift lithium and earns that position through engineering depth rather than just pricing.

Toyota trucks built after 2009 communicate battery status through CAN bus protocols. Dashboard gauges display state of charge, fault codes, and temperature warnings based on data the battery management system transmits. OneCharge invested in protocol integration that most competitors skip. Their batteries communicate correctly. Gauges display accurate information. Fault codes mean what they should mean.

Battery enclosures include ballast masses calculated to match lead-acid weight specifications for each truck model. A 48V/600Ah lead-acid battery weighs approximately 1,080 kg. OneCharge lithium at equivalent capacity weighs 438 kg before ballast. They add 642 kg of steel plate to reach the weight that Toyota stability engineering requires.

Chargers ship configured for the specific battery and truck combination. Configuration errors that plague cheaper suppliers do not occur.

Pricing runs $11,370 to $14,480 for 48V configurations. Higher for 80V applications.

What that premium purchases is proven integration and domestic service infrastructure. When failures occur, technicians respond. Compare that to import channels where warranty claims require international shipping and resolution timelines measured in months.

Reference installations report trucks operating correctly from the first day of conversion. That outcome sounds like baseline competence until a fleet manager experiences three weeks of troubleshooting CAN errors with a budget supplier who has never seen that particular Toyota controller variant.

Flux Power differentiates through third-party certification. UL 2580 listing required testing that most competitors skip: thermal abuse tolerance, mechanical impact resistance, short circuit protection under various fault conditions, environmental stress screening.

Publicly traded status on NASDAQ creates accountability structures that private battery assemblers lack. Financial reporting requirements and SEC oversight produce documentation trails that matter when insurance underwriters ask about equipment specifications.

Pricing runs 11-16% below OneCharge for comparable configurations. Product line coverage is narrower. Not every Toyota model variant has a validated configuration in their catalog. Confirming availability for specific trucks before purchase commitment prevents delays when Flux needs to engineer a custom solution.

Direct imports from Chinese manufacturers price at $6,420 to $8,970 for 48V systems that domestic suppliers sell above $11,000.

Cells typically come from established producers. CATL and BYD supply most of the Chinese export market. Cell quality is not where cost savings originate.

Battery management systems vary dramatically. A properly engineered BMS monitors individual cell voltages, actively balances charge distribution across the pack, tracks temperature at multiple measurement points, and provides protection circuits for overcurrent, overvoltage, undervoltage, and thermal fault conditions. Budget implementations monitor pack-level voltage only, use passive balancing that barely functions, include one temperature sensor for the entire pack, and omit protection features.

Both battery types operate initially. The budget implementation degrades faster as cells drift out of balance and the inadequate BMS fails to correct the divergence. Capacity fade accelerates. Cycle life drops below specifications.

Facilities employing electrical engineering staff comfortable diagnosing lithium battery systems can extract value from Chinese imports. The staff identifies problems before they cascade and manages the pack appropriately. Operations lacking that internal expertise should budget for domestic suppliers with actual support capabilities.

Integration Requirements

Lithium conversion requires charger replacement without exception. Lead-acid charging profiles will damage lithium cells through overvoltage termination and inappropriate charge rate transitions. Any lithium supplier quotation that does not explicitly address charging equipment is either incomplete or assumes the buyer already understands the requirement.

A ten-truck fleet conversion requires ten chargers at $1,580 to $2,740 each depending on power rating and features. That adds $15,800 to $27,400 to project cost. Suppliers who include matched chargers in battery pricing demonstrate system-level understanding. Suppliers who mention chargers only in footnotes or separate line items reveal where their attention focuses.

CAN bus communication matters for trucks manufactured after approximately 2009.

Toyota dashboard instrumentation pulls battery status data through CAN protocols. Batteries with compatible communication show accurate state-of-charge readings and meaningful fault code displays. Batteries without proper CAN integration display frozen gauges, erratic readings, or persistent error codes that operators learn to ignore. The truck operates in either scenario. Operators cannot trust the instrumentation in the second scenario, which leads to trucks running unexpectedly dead during peak operational hours.

Weight compliance cannot be compromised for cost savings.

A 48V/600Ah lead-acid battery weighs 1,020 to 1,140 kg depending on manufacturer and construction. The equivalent lithium pack weighs 410-468 kg. That leaves 560 to 730 kg of counterweight missing from stability calculations. Responsible lithium suppliers build ballast into their enclosures to reach lead-acid weight specifications. Suppliers who ship underweight batteries with vague instructions to "add counterweight as needed" do not understand the application they claim to serve.

Liability Considerations

An underweight battery creates liability exposure. A forklift tipping during normal operation because battery mass falls below engineering specifications generates questions from OSHA investigators, insurance adjusters, and potentially plaintiff attorneys. The cost savings on ballast steel looks different in that context.

Model-Specific Notes

7FB and 8FB series represent the bulk of Toyota electric forklift installations in North American warehouses. Aftermarket support for standard configurations is mature. East Penn and OneCharge both maintain validated battery specifications. Installation procedures are documented. Compatibility surprises rarely occur for buyers who verify specifications before ordering.

7FBR reach trucks require more careful dimensional verification.

Battery compartments run tighter than counterbalance models. Catalog specifications sometimes fail to capture production tolerance variations across model year changes. Measuring the actual compartment with physical tools prevents ordering batteries that do not fit the truck. Reach trucks also operate in narrow aisle configurations where stability margins carry greater consequence. Weight specification compliance deserves particular attention.

8FB controllers pull more diagnostic data from battery management systems than earlier truck generations. The controller expects richer information and throws fault codes when it does not receive expected data fields. Lithium suppliers claiming compatibility based only on dimensional fit may not have verified CAN protocol communication. Requesting installation references specifically from 8FB fleet conversions before committing purchase orders prevents integration problems.

7FBH and 7FBMF high-capacity models have limited aftermarket battery availability.

Manufacturing economics favor high-volume configurations. A 48V/1000Ah battery for heavy-duty trucks represents a smaller market than standard 500-600Ah configurations for typical warehouse equipment. Lead times for large-format batteries extend to four to six weeks when suppliers need to manufacture rather than ship from inventory. Confirming specific availability and realistic delivery schedules before committing prevents procurement delays.

Summary

Toyota dealer batteries cost 37-48% more than equivalent aftermarket alternatives without delivering measurable performance advantages. The premium funds dealer margin structures, not superior manufacturing or materials.

High-utilization facilities running above six hours daily reach lower five-year ownership cost with lithium despite initial sticker shock. OneCharge and Flux Power have solved the integration engineering that trips up budget suppliers.

Low-utilization facilities running below six hours daily achieve lowest ownership cost with East Penn lead-acid at 35-44% below Toyota dealer pricing. Maintenance burden stays manageable when daily operating hours remain below the threshold where backup battery requirements trigger secondary costs.

The analysis draws from fleet performance tracking across client facilities from 2019 through 2024. Specific results vary with utilization patterns, regional energy pricing, local labor costs, and maintenance practices.