What's the Difference Between an AGM Battery and a Regular Battery?

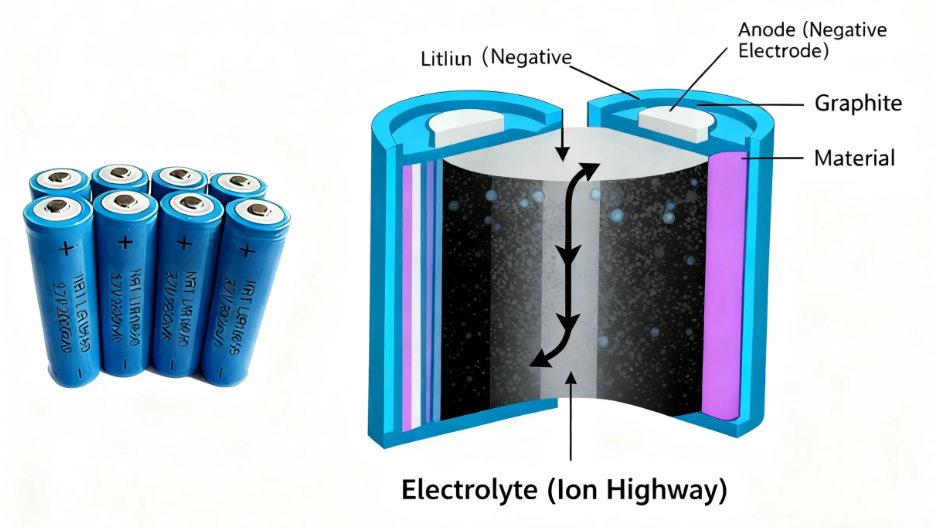

The Chemistry Nobody Needs to Memorize

Both run on the same reaction. Lead plates sit in sulfuric acid. Discharge turns them into lead sulfate. Charging reverses it. Done.

The interesting part is what happens to the acid itself.

Lead plates corrode in sulfuric acid. No way around it. The positive grid slowly converts to lead dioxide and eventually to lead sulfate that doesn't conduct electricity anymore. The negative plate grows a forest of lead crystals that can eventually short against the separator. Both plates shed active material as the paste fatigues from repeated expansion and contraction during charge and discharge cycles.

All lead-acid batteries die the same deaths. The question is which design postpones those deaths longest for a given application.

Why Liquid Acid Causes Problems

In a regular flooded battery, the acid floats free. Seems fine until the math lands: sulfuric acid is almost twice as heavy as water. Leave the battery sitting for a week and the strong acid sinks to the bottom. Weak acid rises to the top.

Now different parts of each plate are working in different concentrations. The bottom corrodes faster. The top sulfates faster. The whole battery ages unevenly. Capacity drops and nobody can see why from the outside.

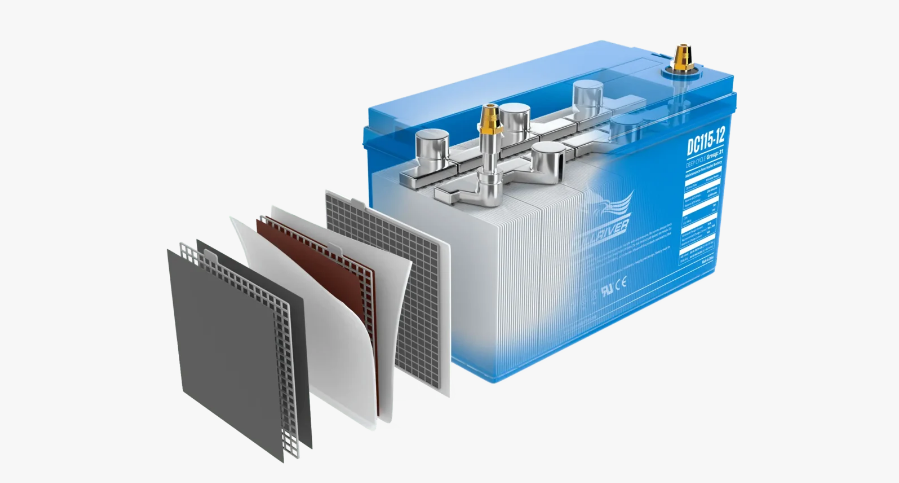

The internal construction of a battery determines its performance characteristics and longevity

The fix is equalization charging. Crank the voltage up to 15 or 16 volts, boil the electrolyte, let the bubbles stir everything back together. Works fine but eats water. Do it too often and the plates dry out. Do it too rarely and stratification wins anyway.

Flooded batteries have lived with this problem since 1859. Every design improvement tries to slow it down. None of them stop it.

Tall batteries stratify worse than short ones. Batteries that sit unused stratify worse than batteries that cycle regularly. Batteries charged at low current stratify worse than batteries charged hard enough to gas. The physics are inescapable.

Some manufacturers tried adding mixing devices, little pumps or agitators built into the cells. Too expensive for automotive use. Too prone to failure. The industry gave up on mechanical solutions decades ago and accepted that flooded batteries need periodic overcharging to survive.

What AGM Actually Does

AGM wraps the acid in glass fiber blankets. The fibers are thin, maybe a micron or two in diameter, and they hold acid the way a sponge holds water. Surface tension keeps everything locked in place.

No flowing liquid means no stratification. Problem solved. But the engineers who built the first AGM cells for military jets in the 1970s stumbled onto something better.

They left the glass mats slightly undersaturated. About 92 or 93 percent full. The empty space forms tiny gas tunnels running through the separator.

During overcharge, oxygen bubbles off the positive plate. In a flooded cell this gas escapes through the vents and takes water with it. In AGM the oxygen travels through those tunnels to the negative plate and reacts with the lead there. The reaction makes water. The water stays inside. The cell stays sealed.

Recombination efficiency runs close to 99 percent when charging is done right. This is why AGM batteries never need water added. This is why they can mount sideways or upside down. This is why Porsche puts them in the front trunk of the 911 where a flooded battery would be illegal.

The compressed sandwich construction creates another advantage that gets less attention: lower internal resistance.

In a flooded battery, ions travel through bulk liquid to reach the plate surfaces. The path length depends on how the plates are spaced and how thick the liquid film is. In AGM, the separator presses directly against the plates. Ions travel through wetted glass fibers with almost no gap to cross.

Shorter paths mean lower resistance. Lower resistance means less voltage drop under load. Less voltage drop means more power reaches the starter motor.

Under the hood, battery technology directly impacts starting performance and electrical system reliability

The numbers are not small. AGM internal resistance typically runs 30 percent lower than flooded batteries of similar capacity. In cold weather, when the electrolyte thickens and electrochemical reactions slow down, that 30 percent margin can make the difference between an engine that fires and an engine that groans once and dies.

Cold cranking amp ratings reflect this. A Group 48 AGM might rate 760 CCA where a flooded battery in the same case hits 600. Same size, same weight, 25 percent more starting power. That margin matters when temperatures drop below zero.

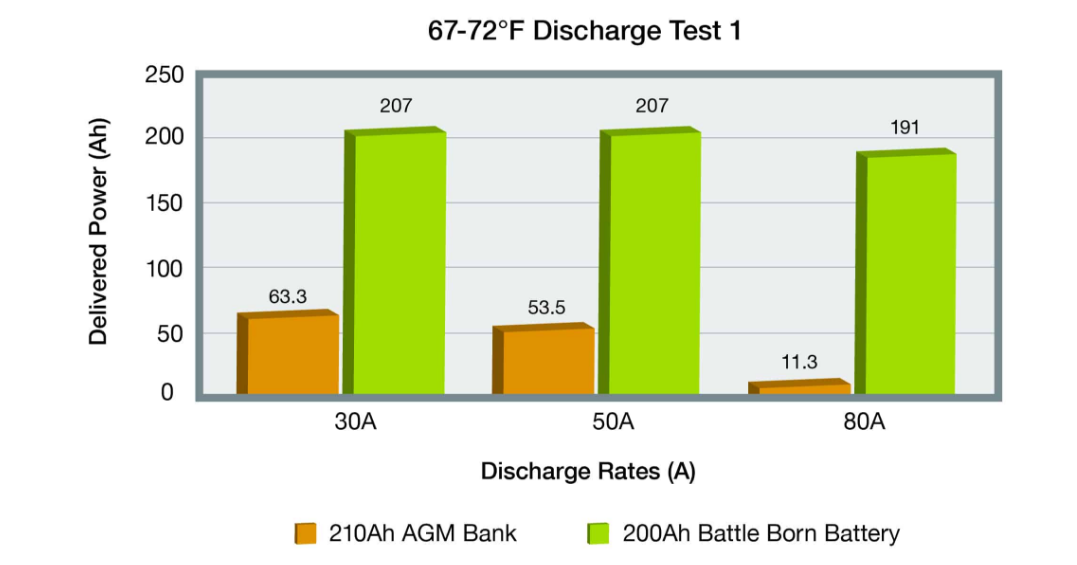

The Real Performance Gap

Forget the marketing specs for a minute. The difference that matters most is charge acceptance.

A flooded 60Ah battery might absorb 8 or 10 amps efficiently when it's half empty. An AGM of the same size takes 20 to 25 amps without breaking a sweat.

Why does this matter? Because modern cars with start-stop systems kill the engine at every red light. Each restart pulls maybe half an amp-hour out of the battery. In city traffic that adds up to 30 or 40 restarts per hour. The alternator only runs in short bursts between stops.

Modern start-stop technology demands battery performance that flooded designs cannot deliver

Flooded batteries cannot keep up. They fall behind on charge, a little more each cycle, until one morning the engine won't crank. This is not theory. BMW learned it the hard way in the early 2000s when they tried using conventional batteries in their first start-stop 3-Series. Warranty claims went through the roof. Now every start-stop car on the market specifies AGM or at minimum an Enhanced Flooded Battery.

The other gap that matters is cycle life. Run a flooded battery down to 50 percent repeatedly and it might last 250 cycles. Run an AGM the same way and expect 500 or more. The Optima YellowTop and Odyssey PC series built their reputations on exactly this. RV owners figured it out years ago. So did the off-grid solar crowd.

Where AGM Falls Apart

Sealed construction cuts both ways.

Overcharge a flooded battery and water boils off. Annoying but fixable. Add distilled water and move on.

Overcharge an AGM and the oxygen recombination system gets overwhelmed. Gas pressure builds. The safety valve pops. Water vapor escapes forever. Do this enough times and the separator dries out. Internal resistance climbs. Capacity craters. No way to reverse it. The battery is toast.

Worse, the recombination reaction generates heat. If the charging system pushes too hard, heat builds faster than the case can shed it. Temperature rises. Reaction rates increase. More heat. Classic thermal runaway. Severe cases melt the plastic casing. Fires have happened.

The voltage window is tight. Flooded batteries tolerate anywhere from 14.2 to 15 volts at room temperature without complaint. AGM needs to stay under 14.8 volts and really prefers 14.6 or lower. A cheap alternator with sloppy regulation can kill an expensive AGM in two or three years.

VARTA and Bosch both publish application guides warning installers about this. Most people never read them.

The aftermarket is full of stories about AGM batteries dying young. Forums are littered with posts from owners who bought premium batteries and got two years out of them. The pattern is consistent: vehicle with aggressive charging, owner unaware of the voltage sensitivity, battery slowly cooked until it quit.

Jeep Wranglers with aftermarket winches are notorious for this. The dual-battery setups often use isolators or solenoids that connect both batteries to the alternator simultaneously. If the charging voltage runs high, both batteries suffer. The AGM in the auxiliary position often fails first because it sees full charge current without the temperature compensation the main battery gets.

Marine applications show similar patterns. A boat alternator sized for rapid recharging after heavy discharge can easily push 15 volts or more. Fine for flooded batteries that can vent the excess. Deadly for AGM batteries that cannot.

Marine environments present unique charging challenges that can stress AGM batteries beyond their limits

The fix is proper voltage regulation, ideally with temperature sensing mounted directly on the battery case. External regulators from Balmar, Wakespeed, and Electromaax solve the problem but add cost and complexity. Most boat owners skip this step and wonder why their expensive batteries only last two seasons.

The Temperature Problem Nobody Mentions

AGM batteries hate sustained heat worse than flooded batteries do.

Both types suffer accelerated aging in hot climates. But when a flooded battery loses water to evaporation, it can be replenished. When an AGM loses water to thermal stress, that capacity is gone permanently.

A flooded battery in Phoenix requiring water every few months will outlast an AGM slowly cooking itself to death in the same engine bay. This runs counter to everything the marketing materials suggest. Interstate Battery technicians in the Southwest have been saying it for years. So have the fleet managers running delivery trucks in Texas and Florida.

For hot climate applications with easy battery access, flooded technology often makes more sense. This is not a popular opinion in the industry. It remains true.

Heat accelerates every chemical reaction inside a battery. Grid corrosion speeds up. Self-discharge increases. Water evaporates faster. The rule of thumb: battery life halves for every 10 degrees Celsius above 25.

An AGM battery rated for 5 years at room temperature might last 2.5 years at 35 degrees average and barely 18 months at 45 degrees. Engine compartments in hot climates routinely exceed these temperatures. The battery bakes every time the car sits in a parking lot.

Extreme heat poses the greatest challenge to AGM battery longevity

Flooded batteries suffer the same acceleration but tolerate it better because water loss is correctable. The owner who checks electrolyte levels every oil change and tops up as needed can keep a flooded battery alive for years past its expected service life. No such option exists for AGM.

Some manufacturers now offer AGM batteries with enhanced heat tolerance. Exide Edge and a few others use proprietary separators and electrolyte formulations designed for high-temperature survival. Whether these improvements justify the premium over standard flooded batteries in hot climate starting duty remains debatable. The warranty periods do not differ enough to settle the argument.

Cycle Life in Practice

Published cycle ratings come from lab conditions that rarely match real use.

The Trojan T-105 flooded golf cart battery has been the deep cycle benchmark for decades. Properly maintained with regular watering and equalization charges, owners routinely report 5 to 7 years of service in daily golf cart duty. That means somewhere around 1000 to 1500 cycles at moderate discharge depths.

Premium AGM batteries like the Lifeline GPL series or the Northstar NSB series match or exceed this, but at three to four times the purchase price. Whether the premium pays off depends entirely on whether the application can deliver proper charging.

Off-grid solar systems with sophisticated charge controllers get full value from AGM. A boat with a single alternator and no temperature compensation often does better with flooded batteries that can survive the abuse.

Off-grid applications with proper charge controllers extract maximum value from AGM technology

The single biggest killer of both battery types is chronic undercharging. Partial state of charge operation lets sulfate crystals grow on the plates. Small crystals from normal discharge dissolve readily during recharge. Large crystals from prolonged partial discharge do not.

Once sulfation sets in, the battery loses capacity permanently. Desulfation chargers and pulse treatments sometimes help marginally but cannot restore a heavily sulfated battery to full health. Prevention beats cure every time.

AGM batteries are more forgiving of partial state of charge than flooded batteries because the higher charge acceptance allows faster recovery when charging current becomes available. But even AGM suffers if left sitting at 60 or 70 percent for weeks at a time. Float charging is not optional. Solar maintenance chargers exist for a reason.

Flooded batteries show sulfation symptoms more obviously. The specific gravity readings drop and stay low. The battery accepts less and less charge current. AGM hides the damage better. Internal resistance creeps up. Starting performance degrades gradually. By the time the battery fails to crank the engine, the damage is terminal.

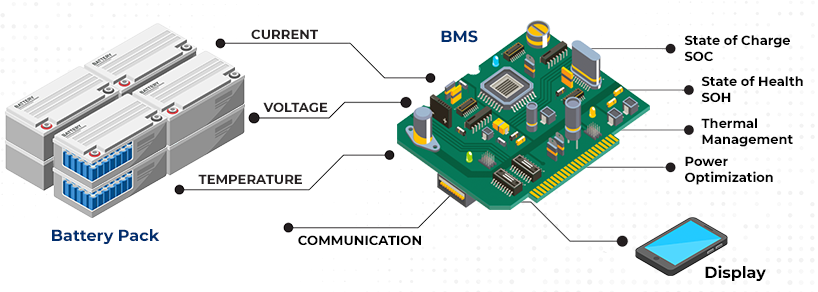

The Start-Stop Question

If the vehicle has start-stop technology, AGM is mandatory. Period. Installing a flooded battery will cause system failure within months. The battery management system expects AGM-level charge acceptance and will not function without it.

If the vehicle came with AGM from the factory, replacing it with anything else requires reprogramming the charging system. Most shops skip this step. Most of those replacement batteries fail early.

Audi and Mercedes service bulletins specifically address this. The correct procedure involves registering the new battery with the onboard computer so it adjusts charging strategy appropriately. Skipping registration leads to either undercharging (shortened life) or overcharging (thermal damage).

Modern vehicles require sophisticated battery management systems that must be properly configured

This registration requirement is why AGM replacement at a dealer costs more than parts and labor alone would suggest. The scan tool session and coding take time. Independent shops with proper diagnostic equipment can do it for less.

The battery management systems in modern vehicles track state of charge, state of health, and charge acceptance in real time. The algorithms assume a fresh battery when first coded. As the battery ages, the system compensates by adjusting charge targets and start-stop behavior.

Install a new battery without resetting the counters and the system keeps treating it like the old one. It may hold back alternator output to protect against overcharging a degraded battery that no longer exists. The new battery never gets fully charged. It sulfates. It fails early. The owner blames the battery brand when the real fault lies with the installer.

VW Group vehicles are particularly sensitive to this. The battery sensor on the negative terminal monitors current flow and calculates state of charge. If the sensor is not recalibrated after battery replacement, the readings drift. The start-stop system becomes erratic. Warning lights appear. The dealership charges diagnostic time to find a problem that proper installation would have prevented.

Brand Differences That Actually Matter

Not all AGM batteries are equal. The glass mat quality, plate thickness, and alloy composition vary significantly across manufacturers.

Odyssey uses thin-plate pure-lead technology that delivers extreme cranking power and deep cycle capability in the same package. The PC1500 can push over 900 cold cranking amps from a Group 34 case while still tolerating 400 deep cycles. The tradeoff is price and a reputation for being sensitive to charging voltage.

Optima spiralwound cells offer superior vibration resistance because the wound construction physically cannot shed active material the way flat plates can. The YellowTop handles both starting and deep cycle duty. The RedTop is strictly for starting. Mixing them up is a common mistake.

VARTA and Bosch AGM batteries dominate the European OEM market. They tend to be more conservatively rated than American brands but extremely reliable within those ratings.

Duracell, DieHard, and other retail brands typically source from one of a few major manufacturers (Clarios, formerly Johnson Controls, makes most of them) and represent decent value without exceptional performance.

RV and marine applications demand batteries built for repeated deep discharge cycles

For marine and RV applications, Lifeline and Northstar have earned strong followings among serious users willing to pay for quality. Lifeline uses a proprietary AGM formulation that handles partial state of charge operation better than most competitors. Northstar emphasizes high charge acceptance for alternator-based charging systems.

Testing methodology matters when comparing brands. Capacity ratings published by manufacturers follow standardized test procedures, usually the 20-hour rate at 25 degrees Celsius. A 100Ah battery delivers 5 amps for 20 hours until voltage drops to 10.5 volts. Clean and simple.

Real-world usage rarely matches test conditions. Discharge rates vary. Temperatures fluctuate. Charging is often incomplete. A battery rated at 100Ah might deliver only 60 or 70Ah in actual service with mixed loads and partial charging.

The brands that perform best in lab tests do not always perform best in the field. Odyssey batteries test brilliantly and deliver genuine performance for owners who provide correct charging. The same batteries disappoint owners with underpowered or poorly regulated charging systems. Lifeline batteries test more modestly but tolerate abuse better.

Independent reviews from boating and RV communities carry more weight than manufacturer specifications. These users log thousands of hours of real service and share results without commercial bias. The consensus views are worth more than any marketing claim.

The Decision Framework

Start-stop vehicle: AGM required, no exceptions.

Deep cycle under 50 percent discharge regularly: AGM pays for itself in longevity. Odyssey, Lifeline, or Northstar for demanding applications. Optima YellowTop for moderate duty.

Hot climate with easy battery access: Consider staying with flooded. The ability to add water compensates for accelerated aging.

Vibration-intensive environment: AGM strongly preferred. Optima spiralwound if budget allows.

Conventional starting duty, no start-stop, moderate climate: Flooded batteries work fine at lower cost. Spend the savings on a quality brand rather than upgrading to AGM.

Sealed installation requirement: AGM mandatory. No flooded battery should ever be installed inside a passenger compartment or in any position other than upright.

AGM technology solves real problems. It eliminates stratification. It enables sealed construction. It delivers charge acceptance that flooded batteries cannot match. In applications that need these capabilities, AGM is worth every dollar of the premium.

In applications that do not need them, AGM is an expensive way to buy shorter service life in hot weather and higher sensitivity to charging system faults.

The battery industry benefits from selling premium products. Buyers benefit from matching technology to actual requirements. These incentives do not always align.