"The risk profile has fundamentally changed since 2015. Battery energy density doubled while aircraft suppression systems remained static. And the certification process for updating those systems, well, it takes years. Nobody wants to ground fleets for that."

— Dr. Michael Chen, Fire Safety Researcher at the FAA Technical CenterChen had been scheduled to present similar findings at a conference in Phoenix the following month. The venue had changed three times due to booking conflicts, a detail he mentioned with visible frustration before returning to the data.

Aviation safety experts have tracked this problem for over a decade as high-energy-density power sources collide with the confined, pressurized reality of commercial aircraft. A smartphone battery fire might ruin a bedside table. The same failure in an aircraft cabin threatens everyone aboard.

Regulations governing lithium batteries on aircraft emerged from incidents and near-disasters, not theoretical risk modeling.

Why Aircraft Systems Cannot Handle Lithium Fires

Lithium-ion technology dominates portable electronics for a simple reason: energy density. These batteries pack considerable power into compact packages, achieving what earlier chemistries could not.

The problem starts with what makes these batteries work. Between them sits an electrolyte solution that conducts ions efficiently but also burns readily. Early laptop manufacturers in the 1990s recognized this trade-off, according to industry veterans, though consumer demand for longer battery life consistently won out over conservative engineering margins.

Lithium-ion batteries pack considerable power into compact packages, but the underlying chemistry presents inherent fire risks.

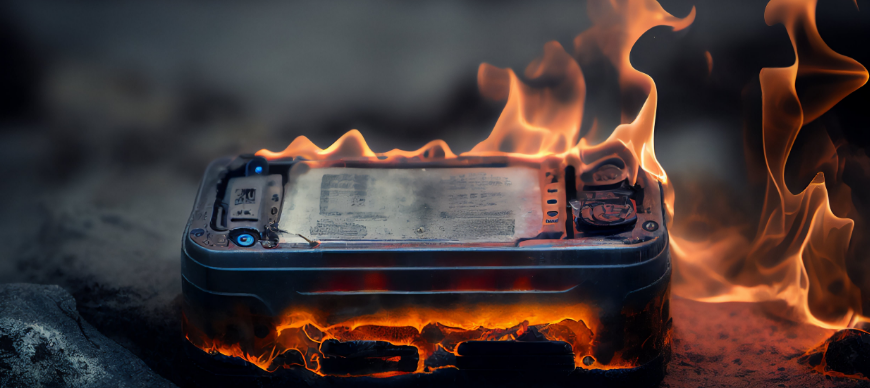

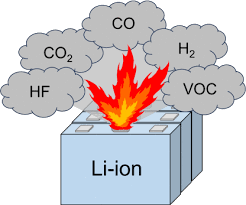

When something goes wrong, the careful balance breaks down. A manufacturing defect. A hard impact. An electrical fault. Heat builds. One cell fails and ignites its neighbors.

Ground-level thermal runaway causes property damage and occasionally injuries. At cruise altitude, risks multiply. Limited cabin air volume becomes a factor. Ventilation systems spread smoke and toxic gases through the aircraft. Fire suppression is limited to handheld extinguishers and cargo-hold halon systems designed for different fire types.

The calculus changes entirely when an aircraft is still on the ground.

On January 28, 2025, Air Busan Flight 391 had not yet departed Gimhae International Airport when smoke appeared from an overhead compartment. Ground-based emergency crews reached the aircraft within minutes. Passengers evacuated directly onto the tarmac rather than down emergency slides at altitude. Every advantage favored a contained outcome.

The fire still injured 27 people. Three required extended hospitalization. Korean aviation authorities later declared the Airbus A321 a total loss. Investigators traced the cause to a power bank with degraded internal insulation.

Aviation concerns about lithium batteries predate smartphones. Cargo shipments of lithium metal batteries caused incidents in the 1990s, a fact often missing from contemporary coverage. Regulatory frameworks have been catching up ever since. Current rules reflect compromise between safety considerations and the reality that millions of passengers now travel with multiple battery-powered devices.

The Boeing 787 Dreamliner battery fires of 2013 briefly redirected industry attention toward aircraft power systems rather than passenger devices. The entire 787 fleet was grounded for three months. That episode involved lithium-ion batteries integrated into the aircraft itself, a different engineering problem, though the underlying chemistry remained identical. Some battery researchers have noted the irony that aircraft manufacturers faced stricter scrutiny for their own battery choices than passengers bringing equivalent energy densities aboard in backpacks.

Cargo holds present their own set of problems, though the dynamics differ from cabin fires. Halon suppression systems work by chemically interrupting combustion, but lithium battery fires generate their own oxygen through thermal decomposition. A cargo-hold battery fire can spread before detection systems register the threat. This is the core reason spare lithium batteries are banned from checked luggage.

Installed Batteries Versus Spares

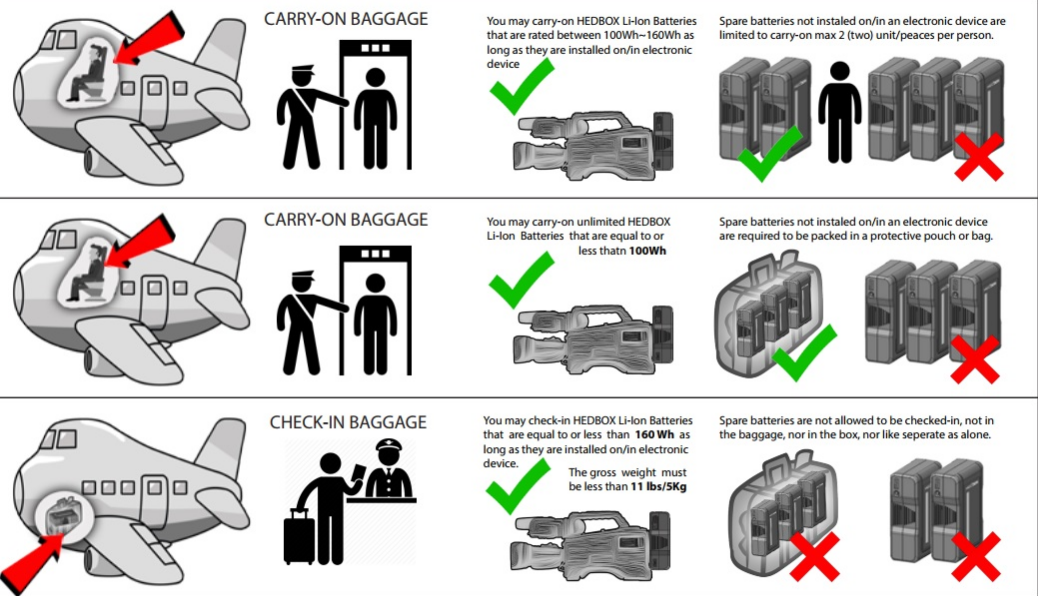

Batteries installed in devices can travel in carry-on or checked baggage under certain conditions. The device must be completely powered off. Sleep mode still generates heat and drains battery. Protection from accidental activation matters. Physical damage must be prevented.

Installed batteries benefit from host-device engineering. Battery management systems monitor temperature and voltage. Protective casings absorb impact. Thermal dissipation prevents dangerous heat buildup.

The FAA recommends keeping battery-powered devices in accessible carry-on baggage. Response time drives this recommendation. Cabin crew reach a smoking device in seconds. Cargo-hold fires may burn undetected before suppression systems activate.

Spare batteries face stricter treatment.

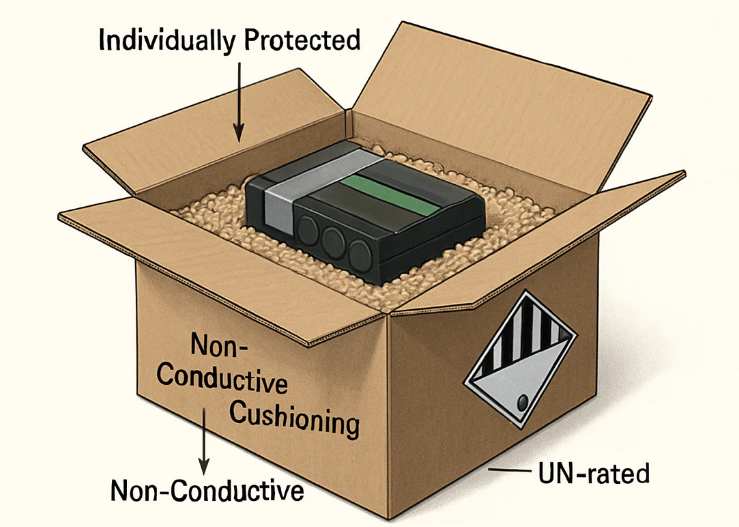

Every uninstalled lithium-ion battery, power bank, and external battery pack travels in carry-on baggage only. Outside their engineered enclosures, batteries lose thermal management and short-circuit protection. They shift in luggage, contact metal objects, experience crushing forces.

Gate-check scenarios generate confusion. When overhead bins fill and airlines check carry-on bags at the gate, passengers must remove all spare batteries and power banks first. These items stay with the passenger in the cabin.

Short Circuits and Terminal Protection

Short circuits cause a large portion of battery incidents. Battery terminals contacting conductive materials create unintended current paths. Keys. Coins. Other batteries. The resulting heat can trigger thermal runaway even in undamaged cells.

FAA regulations mandate terminal protection through several methods. Original retail packaging provides optimal protection with plastic terminal covers and cell separation. Electrical tape over terminals works for batteries outside original packaging. Individual plastic bags or purpose-built terminal covers also satisfy requirements.

"Terminal protection is the thing everyone overlooks. Passengers assume separation in a bag equals protection. But even brief terminal contact generates heat. The physics just does not work the way people expect."

— Jennifer Walsh, Senior Safety Analyst at the Air Line Pilots AssociationShe mentioned that her own father, a retired mechanic, still tosses loose AA batteries into his toolbox. Years of warnings from her have not changed the habit.

Walsh had spent the previous two years compiling incident reports from member pilots. The database now contained over 400 entries, though she acknowledged that categorization remained inconsistent. Some pilots reported smoke events under electrical anomalies rather than battery incidents. Others filed nothing at all unless flames appeared. The union had discussed standardizing reporting procedures at three consecutive annual meetings without reaching resolution.

Items That Cannot Fly Under Any Circumstances

Certain lithium battery items cannot travel on passenger aircraft.

Damaged batteries are prohibited regardless of packaging or capacity. Swelling or leaking cells. Corrosion. Physical deformation. External inspection cannot reliably assess internal damage.

Recalled batteries and devices containing them are prohibited until the recall issue is resolved through manufacturer repair or battery replacement.

Electronic cigarettes and vaping devices occupy a distinct regulatory category. They are prohibited from checked baggage and from charging or use during flight. FAA incident tracking revealed that vaping devices ignite fires in checked baggage at rates disproportionate to their prevalence.

Capacity Thresholds

Battery capacity determines regulatory tier. Aviation regulations measure lithium-ion capacity in watt-hours, quantifying total energy storage.

Most consumer electronics fall below 100 watt-hours. Smartphone batteries sit at roughly 10-15 Wh. Standard laptop batteries range from 40-90 Wh. Tablets typically contain 20-40 Wh. No airline approval is required for any of these. Milliamp-hour ratings require division by 1,000 first.

Professional equipment batteries often reach 101-160 watt-hours. Extended-life laptop batteries. Professional video gear. Some portable power stations. These require airline approval before travel. Passengers can carry up to two spare batteries in this range with approval.

Lithium-ion batteries exceeding 160 watt-hours are prohibited on passenger aircraft. Shipping requires dangerous goods cargo procedures: specialized packaging, documentation, labeling, and handling unavailable to ordinary passengers. A 44,000 mAh power bank at 3.7 volts equals 162.8 watt-hours. Over the limit, despite resembling smaller permitted units.

The Air Busan Fire

The details of Air Busan Flight 391 warranted closer examination by Korean authorities.

Captain Park Sung-ho led the Korean Aviation Safety Board investigation. The overhead bin location emerged as the critical variable. Out of sight. Harder to access. Smoke had time to build before anyone noticed. By the time cabin crew reached the compartment, the fire had spread to surrounding luggage and bin materials.

"Thirty seconds made the difference here. Maybe less. That is the gap between an evacuation and something much worse."

— Captain Park Sung-ho, Korean Aviation Safety BoardHe spent considerable time discussing the cabin layout of the A321 and how the bin design affected crew response time. Park also described the challenge of obtaining maintenance records from the airline, a process that required formal requests through multiple administrative channels. The power bank manufacturer, based in Shenzhen, had ceased operations eighteen months prior to the incident. Investigator attempts to contact former company representatives produced no useful information.

South Korea's Ministry of Land, Infrastructure and Transport announced new requirements effective March 1, 2025. Power banks now require visible storage during flight operations.

Before Leaving for the Airport

Start with inventory and inspection. List every battery-powered device and spare battery planned for travel. Inspect each for damage. Look for swelling, dents, terminal corrosion. Check for unusual odors suggesting electrolyte leakage. Feel for unexplained heat. Damaged batteries stay home.

Cross-reference manufacturer recall lists. This matters particularly for power banks and smartphones from 2016-2020 when several major recalls occurred.

Verify capacity next. Check watt-hour ratings on all power banks and extended laptop batteries. The rating appears on the battery itself, in device specifications, on original packaging, or manufacturer websites.

Protect every spare battery terminal without exception. Original packaging works best. Electrical tape on both terminals provides adequate insulation. Individual plastic bags suffice when other options are unavailable.

Proper preparation before reaching the airport can prevent delays and ensure compliance with battery regulations.

At Security Screening

TSA procedures target lithium batteries specifically.

Laptops and large electronics typically require removal from carry-on bags for separate screening. This allows X-ray examination of battery compartments without obstruction. Phones and tablets usually remain in bags unless officers request otherwise.

Officers can require passengers to power on any electronic device. Dead batteries may result in device prohibition from the aircraft.

Power bank inspections cause most battery-related screening delays. Officers can refuse boarding to passengers with batteries lacking visible capacity markings or obviously exceeding 100 Wh without documented airline approval.

International flights face additional scrutiny. Japan and South Korea strengthened inspection procedures following 2025 incidents. Korean airports reportedly added dedicated inspection lanes for passengers carrying multiple electronic devices.

Delta Flight 1334

The battery pack that ignited on Delta Air Lines Flight 1334 had been dropped the previous week.

Whether that drop caused the failure remains unconfirmed, though investigators noted visible case damage consistent with impact. The owner had apparently decided it still worked fine.

The flight was en route from Atlanta to Fort Lauderdale in August 2025. The device was inside a backpack in a seat-back pocket. Not visible. Not easily accessible. The crew estimated a two-minute delay between first smoke and source identification.

Once cabin crew located the source, trained protocols engaged. Halon extinguishers to suppress flames. Water to cool the battery and prevent reignition. Immediate flight deck communication. Pilots declared an emergency and diverted to Fort Myers. All 191 passengers evacuated safely via normal exits.

FAA safety data through August 2025 reveals a pattern. Power banks account for disproportionate problems relative to their luggage presence. The market expanded rapidly. Quality control varies enormously across manufacturers and price points.

Storage location affects outcome severity. Overhead bins delay detection while placing batteries near materials that sustain fire. In-flight charging adds stress. Batteries outside direct supervision produce worse outcomes when failures occur.

The agency had planned to release updated guidance in September 2025. Internal disagreements over specific watt-hour thresholds delayed publication. Industry groups submitted conflicting recommendations during the comment period. Consumer electronics manufacturers argued for maintaining current limits. Pilot unions pushed for stricter caps. The resulting document, when eventually released, satisfied neither constituency.

None of this information appeared in the airline's initial press release.