What is 9V Lithium Battery?

Modern lithium battery technology has transformed reliability standards for critical electronic devices

The 9V lithium battery solved problems that alkaline chemistry could never touch. When Ultralife Corporation brought lithium manganese dioxide to the rectangular 9V format in the late 1980s, they killed off failure modes that had plagued portable electronics for decades. Smoke detectors dying in cold garages during winter. Wireless microphones fading mid-sermon on Sunday mornings. These problems trace back to alkaline chemistry's fundamental limitations, and they disappeared with lithium.

The smoke detector beeping at 3 AM gets the attention. Professional audio engineers figured out lithium's advantages twenty years ago and never went back. Medical device manufacturers now specify lithium batteries in their user manuals, not as a recommendation but as a requirement. Arctic researchers stopped even packing alkaline batteries because carrying dead weight serves no purpose. The 9V lithium battery earned its place in these demanding applications through performance that alkaline cannot match and likely never will.

The Electrochemical Foundation

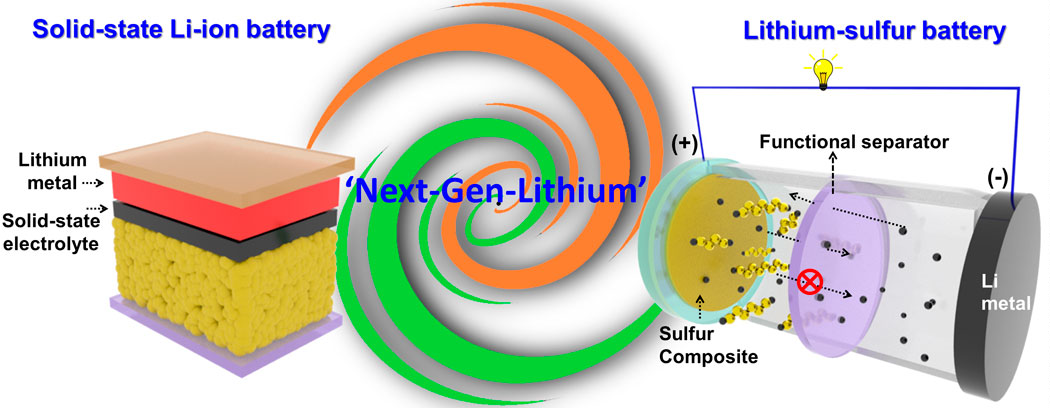

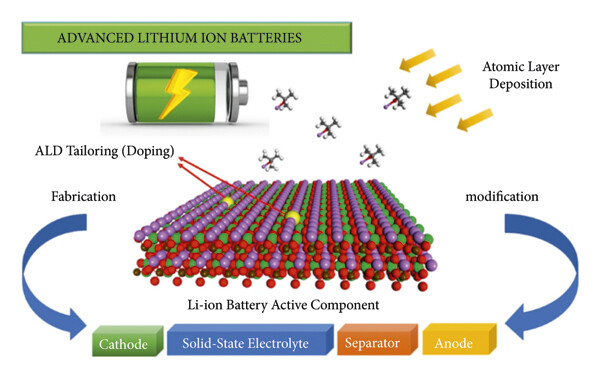

Lithium manganese dioxide chemistry, designated Li-MnO2 in technical literature, explains virtually every performance advantage these batteries deliver.

The lithium anode operates at 3.0 volts per cell versus 1.5 volts for zinc in alkaline batteries. This voltage difference reshapes the entire battery architecture. Alkaline 9V batteries stack six cells in series to reach 9.0V nominal output. Lithium variants achieve the same voltage with three cells. Fewer internal connections, lower cumulative resistance, fewer manufacturing steps where defects can enter the product.

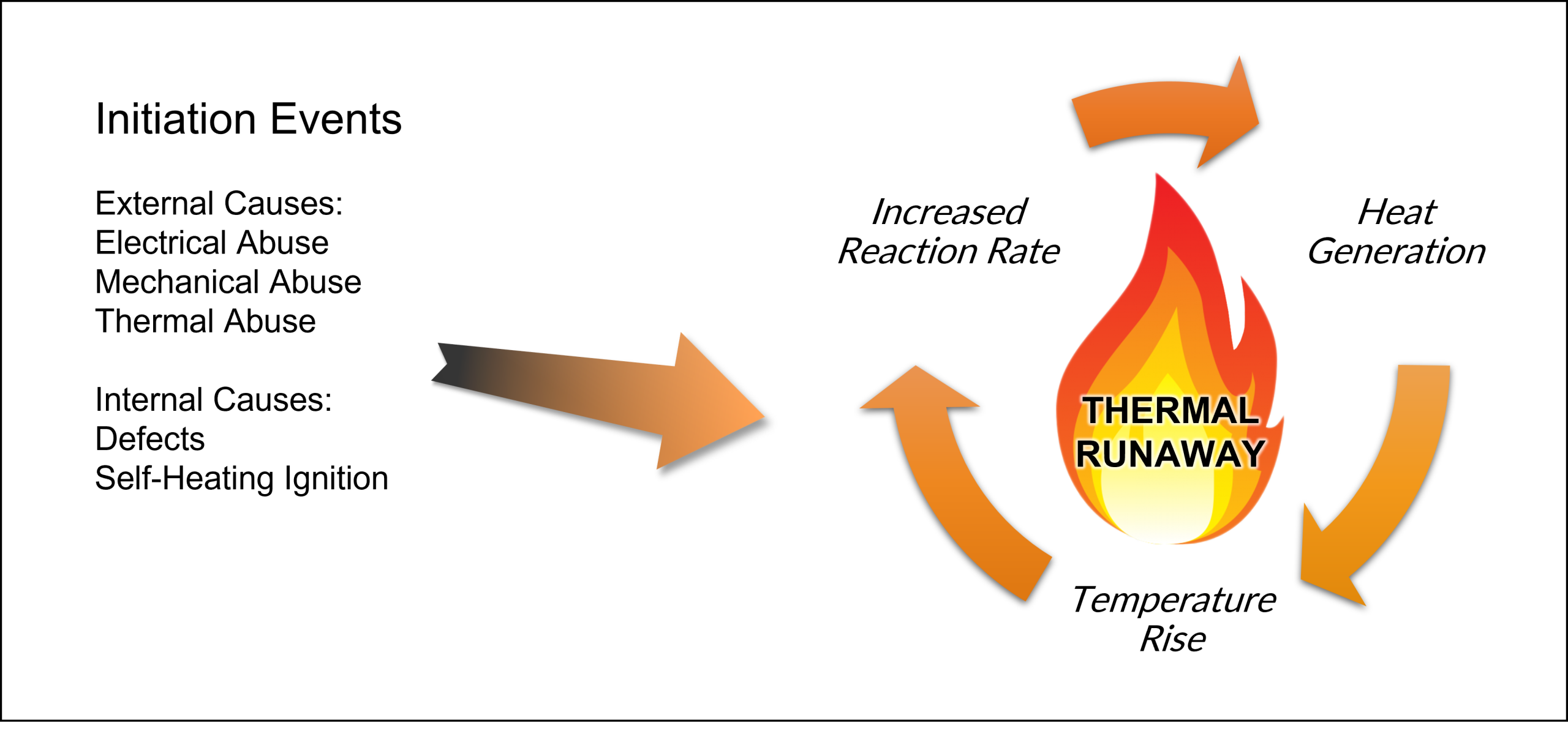

Advanced electrochemical research continues to push the boundaries of battery performance

The manganese dioxide cathode gets overlooked. Other lithium chemistries grab headlines. Lithium cobalt oxide powers smartphones. Lithium iron phosphate goes into electric vehicles. Lithium nickel manganese cobalt runs power tools. Lithium manganese dioxide rarely makes news because it lacks the energy density of cobalt formulations and the cycle life of iron phosphate. What it offers instead is remarkable tolerance for abuse. Li-MnO2 cells survive conditions that would destroy other lithium chemistries. Short circuits that would send lithium cobalt oxide into thermal runaway produce only modest heating in manganese dioxide cells. Temperature swings that would degrade lithium iron phosphate capacity barely register. Storage conditions that would kill lithium nickel manganese cobalt cells within two years leave Li-MnO2 cells functional after a decade.

This robustness matters because 9V batteries end up in smoke detectors installed by homeowners who have never read a battery datasheet and never will.

Alkaline batteries use aqueous potassium hydroxide as their electrolyte, which freezes below 0°C and becomes increasingly viscous as temperatures approach that threshold. Organic solvents in lithium batteries remain fluid at temperatures where water-based electrolytes have long since stopped conducting ions.

Alkaline batteries at -40°C are electrochemically dead. Zero output. The electrolyte has approached solid. Lithium batteries still deliver usable power at that temperature.

Energizer's technical documentation shows capacity retention above 75% at -40°C for their lithium 9V cells. At -20°C, alkaline retains perhaps a third of room-temperature capacity with severe voltage sag under load.

Attic-mounted smoke detectors in Texas and Arizona experience summer temperatures exceeding 50°C regularly. Alkaline capacity drops significantly at those temperatures, and high-temperature storage permanently accelerates degradation through electrode corrosion and electrolyte decomposition.

Voltage Behavior and the Professional Audio Problem

The discharge curve determines whether equipment works properly or spends its life in a degraded state that nobody recognizes as degraded.

Alkaline batteries decline from 9.0V the moment they enter service. The voltage drops continuously throughout discharge. 8.5V after moderate use. 8.0V with further depletion. Eventually reaching levels where most devices malfunction. This gradual slope creates a problem worse than simple capacity loss. Devices designed for 9.0V receive progressively inadequate power throughout the battery's life. The device keeps functioning, but functioning worse with each passing week.

A device powered by a half-depleted alkaline battery is a device operating outside its design parameters. The manufacturer tested with fresh batteries. The specifications assume fresh batteries. The performance guarantees assume fresh batteries. Every day of alkaline battery life moves the device further from the conditions under which it was designed to operate.

Professional audio mixing requires consistent power delivery

Live performances demand reliability from every component

Professional audio is where the voltage behavior difference between lithium and alkaline becomes most visible, because failures happen in real time during live performances where problems cannot be hidden or fixed in post-production. The industry has accumulated enough collective experience with battery-related failures that anyone who spends time on professional audio forums will encounter threads debating lithium versus alkaline, and the debates are not really debates anymore. They are experienced engineers trying to convince skeptics of something the experienced engineers consider settled.

Wireless microphone bodypacks with alkaline batteries exhibit audio quality that degrades gradually as voltage falls. The compander circuit becomes audible. RF signal strength drops, first causing occasional hits when the performer moves to stage edges, eventually causing dropouts even at close range. The alkaline battery reads 7.8V on a multimeter, technically still "good," while the transmitter sounds noticeably worse than it did last week.

Sound engineers troubleshoot these problems constantly without recognizing their source. They blame the venue's RF environment. They blame interference from LED walls, from cell phones in the audience, from the building's HVAC system. They run cable instead of wireless. They add antenna distribution systems and RF coordination software. They spend thousands on spectrum analyzers. The alkaline batteries sitting in the transmitter's battery compartment escape suspicion entirely.

The frustration among audio professionals who have figured this out runs deep. They watch colleagues chase phantom RF problems for hours. They see production budgets absorb expensive equipment purchases that would be unnecessary with different batteries. They sit through meetings where managers question the reliability of wireless technology itself, unaware that the technology works fine when powered correctly.

Lithium batteries maintain 8.8-9.2V for roughly 90% of usable capacity before dropping sharply to end-of-life. The transmitter with lithium power sounds identical on hour eight as it did on hour one. When the battery finally depletes, it depletes fast. The transmitter either works properly or stops working entirely.

The professional audio forums are full of threads on this topic. Pro Sound Web, Gearslutz (now Gearspace), the various Facebook groups where production engineers congregate. The pattern in these discussions is consistent: someone asks about battery choice, experienced users recommend lithium, skeptics push back on cost, and then multiple professionals share stories of chronic wireless problems that vanished after switching chemistries. Rental companies that track service calls before and after mandating lithium batteries report significant drops in wireless-related complaints. The exact percentages vary by company and inventory, but the direction is always the same.

Houses of worship show similar patterns. The "bad wireless" that worship leaders complain about for years, that audio volunteers apologize for Sunday after Sunday, that church boards discuss as a reason to invest in expensive new systems, often vanishes when someone tries lithium batteries.

Bodypacks run eight or nine hours on lithium versus four or five hours on alkaline. Theater productions running three-hour shows with two-hour rehearsals burn through alkaline batteries.

The rechargeable lithium-ion 9V market has grown significantly. These batteries offer 500-600mAh capacity with 1000+ cycle lifespan, eliminating the ongoing cost of primary batteries for high-frequency applications. Professional audio engineers managing large wireless systems increasingly maintain rotation pools. One set in use. One set charging. One set standing by. Full-charge voltage of 8.2-8.4V sits below the 9.0V nominal that some devices expect. Most modern wireless systems tolerate this. Older equipment may not.

Medical Devices

Glucose meters calculate blood sugar from electrochemical reactions whose output depends partly on supply voltage. The compensation algorithms built into these devices work well for small voltage variations. They break down as the alkaline battery approaches end-of-life and voltage falls outside the range the compensation algorithm was designed to handle.

The clinical literature on glucose meter accuracy focuses primarily on test strip variability and user technique rather than battery effects. But the device manufacturers know the issue exists, which is why lithium batteries appear in the specifications for many meters. The specification often appears in small print, easy to overlook. Patients substitute alkaline batteries because they cost less, because they are available at every grocery store, because no one explained why the manual specifies lithium.

Medical devices require precise voltage for accurate readings and reliable operation

Smoke Detectors and Fire Safety

Fire safety professionals replacing batteries across commercial building portfolios report lithium service life of five years or more in detectors that required annual alkaline changes. The sealed detector units with built-in lithium batteries are designed around ten-year service life, with the battery outlasting the sensor element itself.

| Specification | Lithium 9V | Alkaline 9V |

|---|---|---|

| Cost per Battery | $10 | $3 |

| Service Life in Smoke Detectors | 5 years | 10 months |

| Annual Cost | $2.00 | $3.60 (before labor) |

Lithium batteries cost $10 versus $3 for alkaline. Lithium batteries last five years in smoke detectors versus ten months for alkaline. Annual cost runs $2.00 for lithium versus $3.60 for alkaline before counting labor.

Other Applications

Guitar effects pedals present a different case. Analog overdrive circuits produce tone colored by supply voltage. A fresh alkaline battery yields bright, open overdrive. As voltage sags, the tone darkens and compresses. Some players want this. Most do not. The players who want consistent tone use lithium. The players chasing "dying battery" compression stick with alkaline.

Guitar effects pedals demonstrate how battery choice affects artistic expression

Storage and Fire Risk

The 9V battery format creates a unique short-circuit hazard. Both terminals sit on the same end of the battery, exposed, ready to contact any conductive material.

The U.S. Consumer Product Safety Commission has issued safety alerts about 9V battery fires, citing reports of fires caused by loose batteries in drawers contacting steel wool, coins, paper clips, and other metal objects.

The hazard exists with any 9V battery but escalates with lithium because the same chemistry that delivers superior current under normal conditions delivers superior current during a short circuit.

Self-discharge rates for lithium run around 2% annually at room temperature according to manufacturer technical sheets, compared to 5% or more for alkaline depending on storage conditions. A lithium battery stored five years retains over 90% of original capacity. An alkaline battery stored the same duration has lost a quarter or more of its energy to internal corrosion that proceeds whether the battery operates or not.

Proper battery storage prevents potential hazards

Understanding battery chemistry ensures device longevity

Where Lithium Belongs

Smoke detectors, carbon monoxide detectors, security system backups, and emergency equipment should run on lithium batteries. The cost premium disappears when calculated per year of service.

Professional audio equipment belongs on lithium power. Any application where voltage stability affects performance, where reliability matters, where troubleshooting costs exceed battery costs.

Medical devices requiring voltage precision should use lithium batteries.

Alkaline batteries remain adequate for devices used frequently in climate-controlled environments where higher capacity and shelf life provide minimal benefit. A television remote control or a wall clock gains nothing from lithium chemistry.

The 9V format itself is fading from new product designs. USB charging and integrated lithium-ion packs have displaced 9V power in most consumer electronics introduced in the past decade. But hundreds of millions of 9V-powered devices remain in service. Smoke detectors installed decades ago. Wireless microphone systems from the 2000s. Test equipment designed before USB power became standard. Guitar pedals whose analog circuits require the noise isolation that battery power provides.